Contractors can predict the potential outcome of a concrete casting process by using the maturity method, but it can be difficult to apply this technique in the field. This is why Heidelberg Materials, one of the world's largest suppliers of cement, aggregates, and precast and ready-mixed concrete, provides its customers with HETT22, a compiled simulation app that provides timely access to forecasts based on multiphysics models. HETT22 and its associated models were created for Heidelberg Materials by Deflexional, a COMSOL Certified Consultant that specializes in using the COMSOL Multiphysics® software to build multiphysics models and simulation apps. In just six months after launch, HETT22 was downloaded more than 1100 times.

"HETT22 helps you evaluate options from different perspectives," said Mikael Westerholm, project manager for the HETT program at Heidelberg Materials' Cement Sverige. By using simulation to predict potential outcomes of the early-age maturity process, contractors can be more confident in the choices they make regarding construction alternatives — before their decisions are set in stone.

While multiple factors can affect the maturity and strength development of concrete, temperature plays an especially significant role. Concrete that cures quickly in hot weather is likely to be weaker than concrete that matures more slowly under cooler conditions. Below-freezing temperatures can also impair strength development. Contractors can insulate the formwork to mitigate freezing risks or add heat from external sources. Such techniques must be applied judiciously to avoid overheating, premature drying, or significantly increasing construction project costs.

Putting multiphysics simulation into the hands of contractors

HETT22 is the first generation of the program to be developed using the Application Builder in COMSOL Multiphysics and distributed as a standalone simulation app.

"With HETT22, one of our goals was to be as user-friendly as possible," explained Tom Fredvik, technical manager at Heidelberg Materials' Sement Norge. "We have also added new features that enable our customers to consider real-world conditions in more detail."

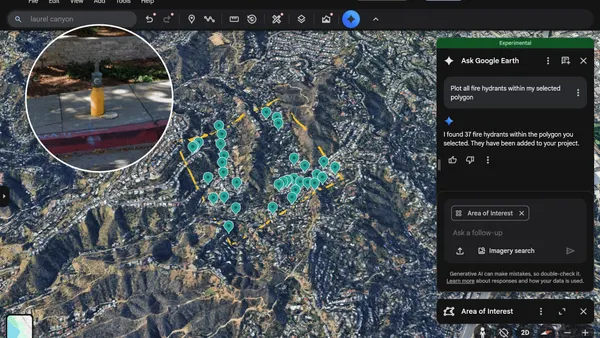

Fig 1- The HETT22 app showing the construction of a sample model

A brief walkthrough of a hypothetical concrete casting project demonstrates HETT22's capabilities (Figure 1). The app user starts by selecting from a list of typical cases and then defines the casting geometry parameters, material mix, strength class of concrete, time frame, and expected weather conditions.

After defining the formwork and geometry, the user can integrate site-specific weather forecasts for the planned casting. Time constraints and desired strength are key influences on a user's choice of materials. "In this example, the strength requirement is set to 15 MPa before we can remove the formwork," said Westerholm, "so we choose a concrete with appropriate strength development from the preinstalled library."

Simulation results guide preemptive adjustments

With the models powering the app, HETT22 yields predictive values for determining how long it will take to achieve the desired strength before form removal. "We can track expected temperatures for the surrounding air and soil and forecast a temperature curve for the concrete itself," said Fredvik. (Figure 2) "Based on our temperature development, we can calculate that it will take about 30 hours for the entire casting to reach the strength that we need." If that is too long for this job, then HETT22 can show the potential effect of different concrete selections on the estimated time for form removal. Builders can select different options from a menu of Heidelberg Materials' concrete products as well as review details about the performance characteristics of each option directly in the simulation app.

Figure 2- Simulation results showing the temperature and strength of a concrete casting

Multiphysics simulation supports cost–benefit analyses

By predicting the effects of choices related to physical conditions, a construction team can use a compiled simulation app to better manage the economics and carbon footprint of each project.

Heidelberg offers its customers hundreds of potential concrete recipes; from the company's perspective, the app is a necessary complement to a potentially daunting array of options. The predictive modeling capability of the COMSOL Multiphysics software, when presented through the app's custom interface, helps users make informed decisions more efficiently.

"This is why we provide HETT22 to our customers," said Fredvik. "Because of the value it adds for them at each decision point of a concrete casting job, we see it as a core part of our tech support offering."

COMSOL Multiphysics is a registered trademark of COMSOL AB.