Mixed-Fleet Capability

1 - What kinds of assets do you want to monitor and track?

-

You may have a mixed fleet of on and off-highway vehicles and equipment or assets from a variety of manufacturers. Your projects and jobsites are an ever-changing mix of workers, vehicles, and equipment. If this is the case, you’ll need to actively monitor many types of assets for your business.

-

Here are a few examples of what our customers track across their fleet

-

Equipment and vehicle location

-

Attachments and non-powered asset location

-

Engine hours and running status

-

Movement history

-

Equipment operator history

-

Vehicle mileage and driver history

-

Inspection and maintenance history

-

-

2 - What should you expect from a solution that supports mixed-fleet operations?

-

Many solutions boast mixed-fleet capability, but that can mean a lot of different things. Consider your current fleet, but also how you see your business scaling in the future. For example, do you envision your business increasing the percentage of rental versus company owned equipment? Or do you have plans to expand your truck fleet and driver teams, so you have less dependence on contract haulers?

-

Here are a few examples of more complex mixed-fleet requirements

-

Rental equipment location and engine hours

-

Monitoring assets from multiple manufacturers in one interface

-

A variety of telematics hardware options to connect different types of assets

-

Driver behavior and safety metrics for trucks and vehicles

-

Driver compliance with electronic logging mandates

-

Vehicle incident reporting and video capture

-

-

Actionable Data

3 - What data do you need to make better decisions on each project?

-

From understanding your fleet’s fuel utilization to minimizing downtime or on-road incidents, it’s important that the telematics solution you choose is able to provide you the data that makes the biggest impact to your business.

-

Here are a few examples of data that telematics software can provide

-

Fuel and fluid levels

-

Fuel utilization

-

Idle time and run time

-

Health and fault warnings

-

Geofence entry/exit alerts

-

Upcoming maintenance alerts

-

Harsh accelerations and braking history

-

Speed limit violation alerts and history

-

-

4 - What data-informed actions are important for your business?

-

Having complete and accurate data is one thing, but you need to turn that data into critical insights for your operation. Making informed and timely decisions for your operation brings you one step closer to minimizing downtime, maximizing uptime, and taking your productivity to the next level.

-

Here are a few examples of the process improvements our customers have put in place based on telematics data

-

Proactive fleet maintenance planning

-

Optimized equipment and vehicle allocation across sites

-

Efficient refueling and lube runs

-

Coordinated equipment pickups and deliveries to sites

-

Truck and loader matching for material hauling

-

Advance warning of possible equipment failure

-

Remote diagnosis and minimized downtime for unplanned repairs

-

-

Ease of Use and Scalability

5 - Can your telematics solution scale with your business and from project to project?

-

A newly implemented telematics solution needs to be easy to configure and use. As you grow your team and your business, you’ll need to add more users and more assets to the organization.

-

Here are a few examples of what you should expect out of telematics software

-

Simple subscription and billing options that bundle hardware, software, and data services into one monthly or annual payment

-

Quick and easy configuration of your operation, and ease in adding new jobsites, drivers, vehicles and equipment

-

Integration with multiple manufacturer telematics data feeds

-

Actionable dashboards and reports that you can configure based on your business needs

-

A cloud based application that can run on any desktop or mobile device

-

Online training and tutorials, and a responsive support team

-

-

6 - Is your telematics solution part of a bigger operating system?

-

In order to maximize productivity, you’ll need greater control over each phase of the construction process. Many telematics solutions are solid solutions for asset tracking, but stop there. A solution that plugs into a bigger set of offerings can give you visibility into everything from managing your fleet to monitoring job site productivity and project cost.

-

Here are a few examples of the power behind a telematics solution that is part of a broader suite of construction software

-

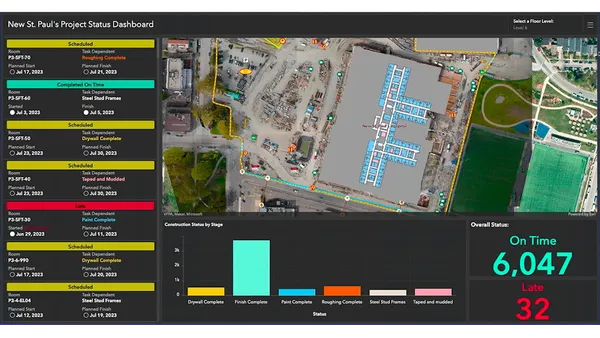

One dashboard to monitor productivity, predict downtime and maximize uptime across all your sites

-

Each project is connected through common jobsite boundaries and definitions across solutions

-

Integrated site design, survey, and as-built information

-

Real-time cut, fill, volume, and compaction data

-

Live daily volume and compaction quality metrics

-

Ability to adjust daily work targets at each site to stay on schedule

-

Accurate site and project cost rollups based on utilization

-

Accurate takeoff and cost estimates for future bids

-

-

There is a lot to consider when choosing the right software for your construction operation. The good news is that the technology keeps improving, the data keeps getting more accurate, and the capabilities keep broadening. What this means for you is that once you find a provider that shares the same vision of how construction management software should work, you'll be on the same roadmap to adapt and grow with that vision.