How real is the upshot for virtual reality and augmented reality to disrupt the AEC sector? Real enough for Minneapolis-based Mortenson to create an entire reality capture division. Led by Ricardo Khan, the company's senior director of project solutions, the Integrated Delivery Advancement Team comprises more than 60 Mortenson employees to provide company-wide leadership and guidance in the applied use of virtual design and construction systems, tools and processes.

“It is in our culture to be a change leader,” said Khan of the leap forward into integrating VR and AR into the company’s internal processes and external collaborations with stakeholders. “We see huge opportunities for VR to improve design-phase outcomes, and we are looking at AR to truly revolutionize how field teams leverage information and contextual knowledge to make the best informed decisions to build safer and with high quality.”

Already seeing success among architects for achieving stakeholder buy-in at the design stage, VR adoption is poised to expand across AEC sectors as advancements in graphic card and hardware technology enable a near seamless VR integration with BIM systems. By layering virtual elements into real-world views of job sites, AR is providing safety, training and real-time installation guidance to jobsite crews. While VR provides a completely immersive, artificial digital environment, AR layers virtual components into a real-time view accessible through a smartphone, tablet, heads up display (HuD) or other interface. Proponents of the technologies say they’re nothing short of revolutionary, and are already redefining traditional design/build processes by enabling greater collaboration and eliminating costs across the construction lifecycle.

From video games to construction

The most substantial impact virtual reality has had thus far within the construction sector has been in the democratization of the design process. VR adopters and system developers herald the technology for its ability to allow non-design professionals and stakeholders to conceptualize and provide critical feedback. Dubbed immersive review, placing stakeholders within a VR environment eliminates the need for them to understand and translate dense two-dimensional blueprints or static renderings.

“Being able to explore more options at the outset is huge,” said George Valdes, vice president of product at Long Island City, NY–based IrisVR, a virtual reality technology developer for the gaming industry that is expanding into the construction vertical. “Getting into an immersive environment and away from a 2-D blueprint world that only architects understand provides much more design and construction planning flexibility, and being able to show changes and adjustments on the fly in real time has impact. It will change the way people think.”

The gaming-to-AEC connection in VR system development is shared by Mill Valley, CA–based software developer Autodesk, which this week opened to public beta an instant VR mode within its Autodesk Live platform. The company’s Stingray design engine used extensively in gaming and for blockbuster movies is being leveraged for VR development in AEC applications, particularly in the design phase where visuals are critically important to decision-making.

“We hear almost unanimously that VR is a much more natural way of reviewing design, that it’s the best tool the design side has gotten its hands on in decades,” said Autodesk senior product line manager Nicolas Fonta. “We’re attempting to let users just click on the VR button and the VR experience starts, not just with small models but with big hospital and stadium projects. Quality and performance improvements over time will make this a new way to think about interacting with design.”

Virtual review, real world savings

Mortenson’s experience using VR as an immersive review tool bares out system vendors' predictions. Like most AEC firms, the company has been constantly challenged by decisions being made too late in the design process that lead to problems in construction and client dissatisfaction. As part of the construction of Penn State University’s Pegula Ice Arena, the Mortenson IDAT team brought arena maintenance staff into a 10-foot-by-10-foot Computer Augmented Virtual Environment to simulate a day in the life at the new arena and get their advice on ways to design the space to best serve day-to-day needs.

“Whether in health care or sports or other verticals, that kind of direct feedback to the construction process is something maintenance professionals and facilities managers and the people who are working in the buildings have never had,” said Taylor Cupp, a senior integrated construction coordinator for Mortenson.

In the medical field, Mortenson's use of VR has allowed nurse practitioners to provide feedback on better locations for wall-installed equipment, saving the company thousands of dollars in change orders for relocating the equipment and the infrastructure behind the wall to support it. At the Pegula arena, maintenance staff were likewise able to identify the proper height of protective glass surrounding the arena and the location of engineering valves to maintain the ice surface. “It allows us in turn to optimize construction," Cupp said. "We can pre-fab, we can modulate, we can deliver a high-quality product cheaper and faster. It is really changing the way we work.”

It’s also making an impact on Mortenson's bottom line. Use of VR and immersive review at the Penn State arena resulted in $475,000 in direct savings, Khan said. At Kansas State University, a VR review of field-level and locker room construction garnered $375,000 in budget savings, and at the Sanford Fargo Medical Center, in Fargo, ND, immersive review prevented over $675,000 worth of change-order rework and medical device relocation. The company’s largest VR coup to date has been $1.7 million in cost avoidance at the Atlanta Braves' SunTrust Park.

AR and the smart jobsite

In addition to leveraging video game system engines to optimize the construction VR experience, software developers like Autodesk and IrisVR are also probing mobile capabilities and advances in hardware to make the viewing experience of VR environments less bulky and less dependent on the environment in which the user is standing when they use the VR tool. To that end, augmented reality via smart glasses or a HuD display could stand to impact jobs once construction begins.

“The primary difference now is that VR is a completely immersive environment while AR allows the layering of digital elements to a real-world view,” said Jean-Francois Chianetta, co-founder and CEO of Augment, a downloadable app interface for iOS and Android operating systems that allows users to create custom AR platforms. “Where things can get fuzzy in construction is when we’re layering so many virtual elements into AR that we begin to ebb back into a completely immersive environment,” he said. In short, the more virtual components added to an AR interface, the closer it gets to resembling a VR environment. The technologies are similar, and they are likely to continue to overlap as they each evolve.

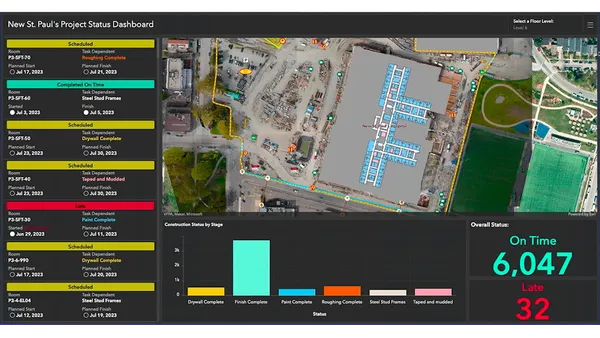

Indeed, AR proof of concept videos developed by the Mortenson IDAT team visualize a jobsite environment where workers, equipment and infrastructure are connected in a web-enabled environment that provides incredible detail on productivity, construction status and timelines, regardless of whether a worker is up-to-date on safety training or if they’re certified for a particular job function.

“We are trying to set the vision of what AR can do for construction with the shortage of knowledge workers in the field,” Khan said. “With the use of a HuD [display], AR can deliver just-in-time knowledge, whether it is a work instruction, a projection of an installation layout onto a concrete slab or any kind of eye-in-the-sky oversight on the job.”

As AR applications develop further, AEC professionals can also expect a swing back toward remote immersive environments, even as those environments provide a real-time, real-world view of a job site. Valdes said prototype systems allowing for remote virtual maintenance and remote virtual inspection are already under development, and could be only a year or two away based on the current pace of advancements in data management capabilities.

“The most important thing for the construction industry to realize with VR and AR is that the technologies are here,” Chianetta said. “They’re here and available and ready to use today.”