Dive Brief

- Virgin Hyperloop One will adopt Autodesk’s Building Information Modeling (BIM) platform and cloud collaboration tools for improved transportation route optimization, digital engineering and workflows, Autodesk said.

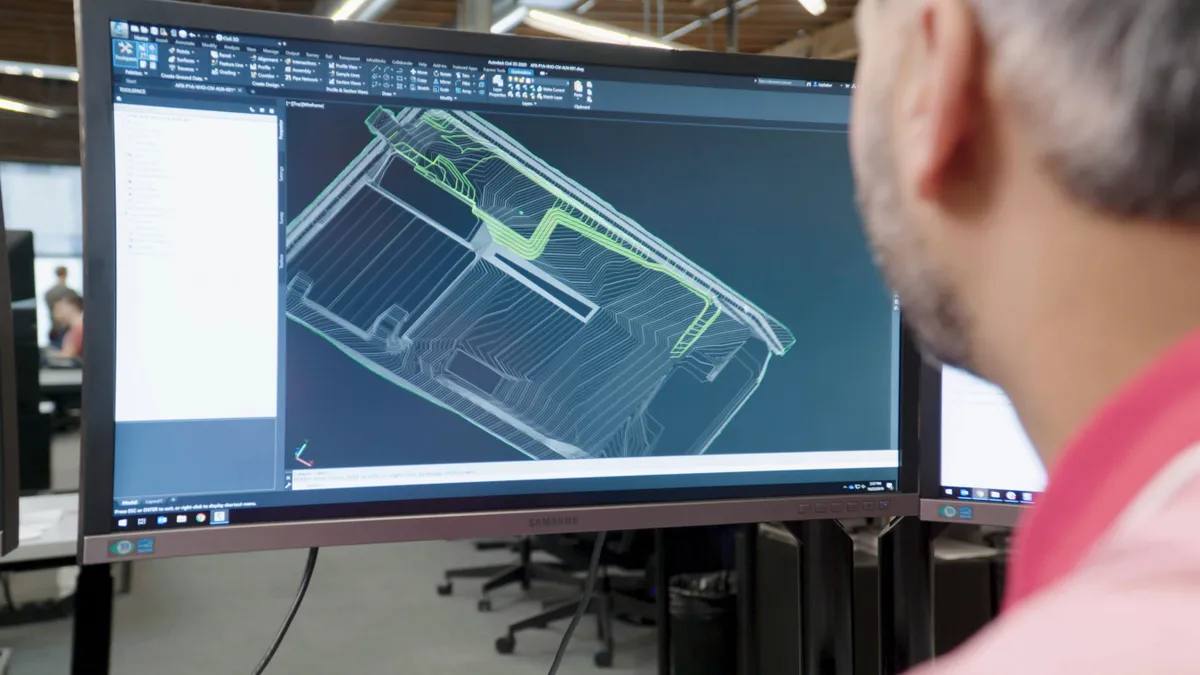

- The planning team on Virgin Hyperloop One uses several Autodesk platforms like Civil 3D, Revit, Infraworks and Inventor. It will now use Autodesk’s BIM 360 tool to help calculate costs and plan an entire project digitally — from design to maintenance — before construction begins.

- Route optimization will allow the company to discover optimal placement for its rails, such if it needs to move a hyperloop system from one type of terrain and to another, an Autodesk official told Construction Dive.

Dive Insight

Virgin Hyperloop One’s technology uses specially depressurized tubes powered by magnetic levitation and electric propulsion to transport passengers or cargo pods at up to 670 miles per hour.

“Virgin Hyperloop One and Autodesk will explore ways to optimize hyperloop routing and operations in a way that not only propels the hyperloop industry forward, but also has ancillary benefits to more traditional forms of transportation such as railway and highway route optimization," Josh Giegel, VHO chief financial officer, said in a statement.

The various, intricate aspects that go into designing high-speed railways is why Autodesk products can help VHO, said Eric DesRoche, manager for infrastructure, business strategy and marketing at Autodesk.

“We believe [Autodesk’s software is] directly appropriate to rail structures and linear assets,” DesRoche said. “And by designing smarter, it helps with the construction phase as well.”

Using Autodesk’s tools — mainly during the design phase for projects like VHO’s — allows teams to connect all the planning stages to see how they work together, DesRoche said. Civil 3D helps with the horizontal alignment, Revit is used for portals and stations along the corridor, and BIM 360 allows every member of the team to work on the same designs virtually.

“This is going to help us optimize that route and provide minimum impact on the environment, pulling vision and thinking into their workflow,” DesRoche said.

Establishing the best route ahead of time and knowing with certainty where to tunnel and where not to will aid with scheduling and adhering to that schedule, he added.

At this point, VHO and Autodesk are still figuring out how to market this optimization to the rail industry, as it’s not being applied to any one project.