Dive Brief:

-

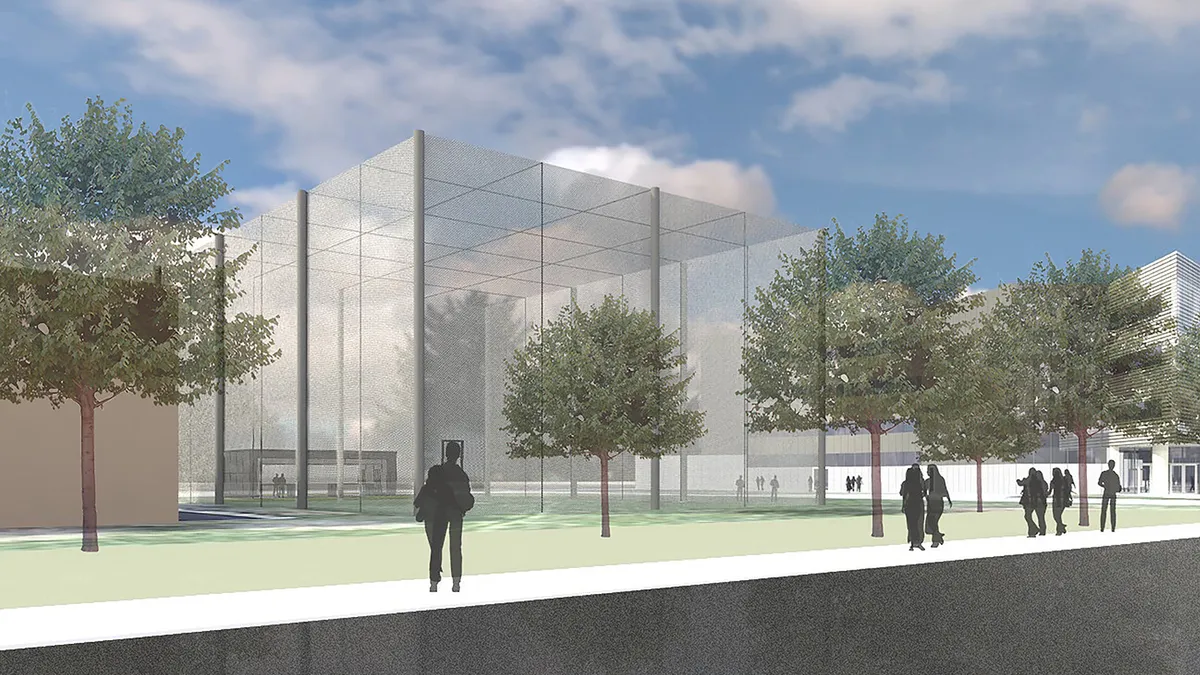

The University of Michigan announced plans to expand its drone-testing facilities with the addition of a four-story netted enclosure where students and researchers can operate drones with fewer Federal Aviation Administration compliance requirements.

-

The new structure will be located next to the new Ford Motor Company Robotics Building, which will open in late 2019 and will include indoor drone testing areas, according to sUASnews.

-

The 9,600-square-foot facility offers a maximum height of 50 feet. It will cost $800,000 to build, with construction starting in August and wrapping up by the end of this year.

Dive Insight:

The Wolverines aren’t the only ones taking drones to school. Corporations are also exploring how the aerial technology can be used to improve their operations. General Electric, for example, is using drones for equipment and factory inspections in the transportation, power, and oil and gas industries. The autonomous drones and crawlers will take photos and get temperature and gas readings in areas that are either inaccessible to or too dangerous for humans.

In the public sector, the Minnesota Department of Transportation said earlier this year that it is looking at drones as one way to lower the costs and traffic delays associated with bridge inspections. Other institutions, companies and municipalities are also weighing the technology.

The host of federal regulations tied to outdoor drone use isn't stopping their adoption, and many drone advocates say the rules are critical to large-scale adoption of the technology. In many ways, the final rules handed down by the FAA last summer offer more clarity on the do's and don'ts of commercial drone use, and streamline the compliance path for some of the most basic uses.

Michigan’s netted enclosure is a tactical approach to research and development with drones in outdoor conditions. Success with new drone hardware or software isn’t often met on the first attempt, and too much regulation can deter innovation.

Although industry-specific drone technology is often tested on construction sites, building a net around a working project is a less-than-practical solution — but that hasn't stopped construction companies from using the technology. Evidence that the industry is pressing forward can be found in the recent partnership between once-rivals 3D Robotics (3DR) and DJI. The former announced this week that its aerial job site scanning software will be available on some of the global drone maker's hardware, opening the software to a broader market.