Dive Brief:

-

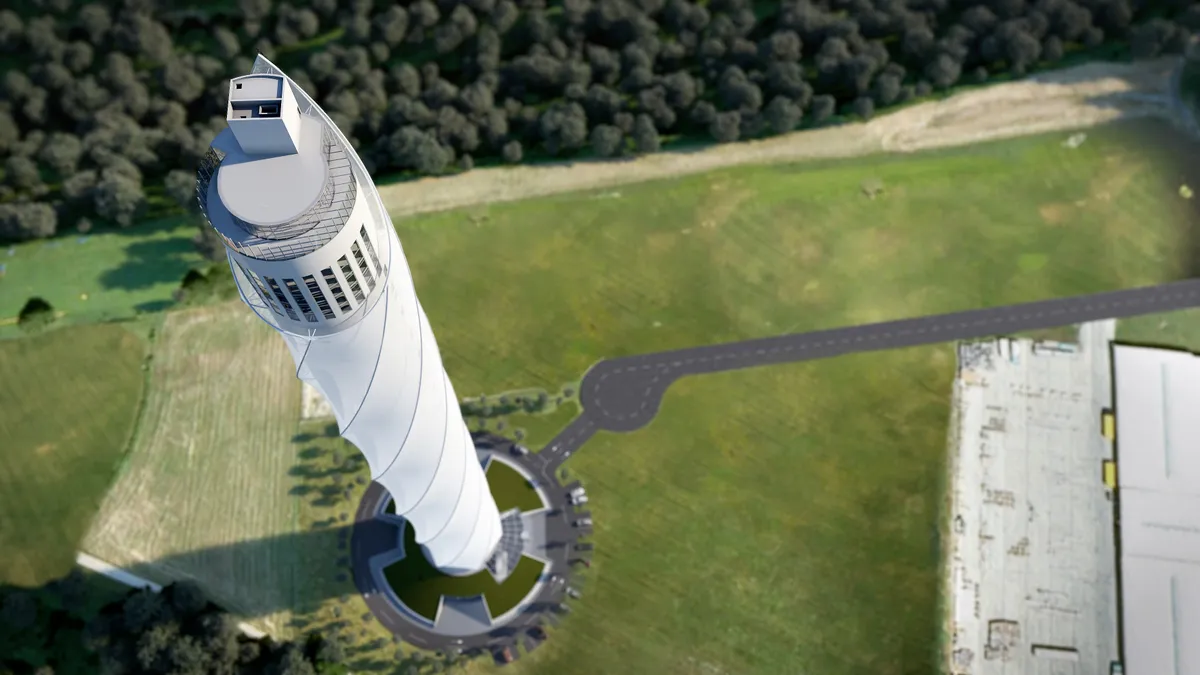

As it completes a 246-meter-tall research and development tower in Rottweil, Germany, early next year, elevator manufacturer ThyssenKrupp will begin testing a magnetic levitation system to move groups of elevator cars vertically and horizontally through shafts equipped with side rails, Engineering News-Record reported.

-

If successful, maglev elevator systems could increase average shaft capacity by 50%, according to the manufacturer, while significantly reducing the amount of mechanical space needed for modern cable elevators.

- German construction firm Zublin acted as the general contractor on the tower, which will feature Germany’s tallest observation deck at 232 meters.

Dive Insight:

With increased speed — ThyssenKrupp's test elevator moves at up to 8 meters per second, ENR reported — cable-free elevators offer greater building access in high rises, supertalls and buildings with unique shapes. The multi-car component of maglev elevators is somewhat akin to putting an airport terminal shuttle train on vertical rails.

Not to be outdone, Japanese global construction firm Obayashi is concurrently at work on a 59,651-mile maglev space elevator for applications including tourism, space exploration and solar power generation. Powered by carbon nanotubes, travelers on the system planned for construction by 2050 need to keep their speed expectations in check: The ride from terminal to terminal is expected to take seven days.

Conventional elevators aren’t being left out in the cold when it comes to technology, either.

ThyssenKrupp has already deployed a HoloLens augmented reality solution for the remote servicing of the world’s 12 million-plus elevators currently in use. Meanwhile, elevator manufacturer Kone debuted its carbon fiber UltraRope in 2013 that use less energy than the heavier steel alternative. The product is being installed in the forthcoming 1-kilometer-tall Jeddah Tower, in Saudi Arabia.