Dive Brief:

- While concrete is a staple for builders, it’s also a top driver of climate change. That’s why many contractors and their suppliers have tested materials that are just as durable, but kinder to the environment.

- Now, two researchers from the Massachusetts-based Worcester Polytechnic Institute have taken this idea one step further. Suzanne Scarlata and Nima Rahbar developed a concrete substitute which can remove greenhouse gases from the atmosphere.

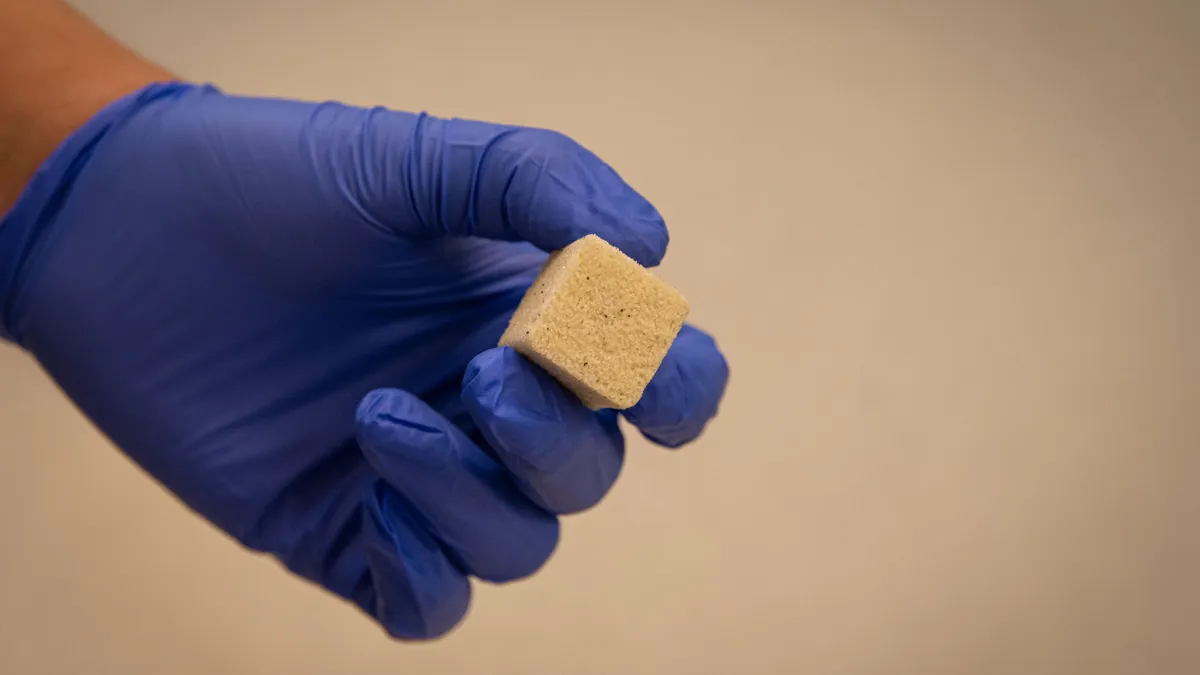

- Besides serving as a material to build new structures, Enzymatic Construction Material (pictured above) is self-healing and the researchers believe it can be used to patch existing concrete.

Dive Insight:

ECM is made of carbonic anhydrase, an enzyme found in living cells. When it connects with CO2, it creates calcium carbonate crystals, ECM’s primary component. Other ingredients of the new mixture include sand slurry and polymer, a binding agent. The result is a material that can remove greenhouse CO2 from the air and safely store it, Scarlata and Rahbar said.

While concrete produces 400 lbs of CO2 per cubic yard, ECM holds about 18 lbs of CO2. In addition, the ECM recycling process is far less energy-consuming than concrete, the researchers said.

While there are other types of alternatives that use bacteria instead of enzymes, they are not as strong as ECM, the researchers said, and the risks of bacteria are unknown.

Concrete: ubiquitous but harsh on the planet

Concrete is the most widely used substance on the planet after water, according to The Guardian, and is quite literally the foundation for modern building. However, there is a massive environmental cost to the material, both from the energy expended in its creation and from how it endures after it’s no longer in use.

Cement use and production accounts for about 8% of global CO2 emissions, according to a 2019 study from the National Academy of Sciences. An alternative building material like ECM could go a long way towards enabling a sustainable construction industry, according to the researchers.

“Although cement is not very expensive, energetically it’s very expensive,” Rahbar said, and it takes a lot of fuel to add the ingredients that make concrete. “Also concrete doesn’t recycle, so when you make stuff it’s just there. In fact, you have to spend extra energy to grind it and make it smaller.”

The future of ECM

While ECM isn’t strong enough yet for apartment buildings, researchers say it could be used on smaller projects with a lower load demand like the side of a house. Currently the material’s strength is around 12 MPa, Rahbar said via email, while typical Portland concrete ranges from 20 - 40 MPa. MPs is a measurement of how much pressure can be applied to the concrete before it cracks or fails, according to Hunker.

The researchers have already patented ECM; it’s licensed to a startup company called Enzymatic Inc. for production as a construction material. Going forward, the researchers plan to improve ECM’s strength so it can be used in larger projects, as well as its resistance to humidity and large quantities of water.

“The technology's there, but needs tweaking and a little more development,” Scarlata said.

At the moment, ECM costs about $168 per cubic yard, Rahbar said, though its energetic costs (in other words, the sum impact of all greenhouse gas emissions attributed to the material across its life cycle) are much lower than standard concrete. Standard concrete prices vary widely, but fall around $125 per cubic yard, according to Concrete Network.

Next steps for Scarlata and Rahbar include conducting more testing and demonstrations, and seeking grants for additional research. The researchers hope that ECM can be used in the near future in areas where there are not a lot of financial or other resources to create concrete, Scarlata said.

Creating a low-energy building material to reduce the industry’s carbon footprint is the ultimate goal that guides the two. Said Rahbar: “It’s our contribution to climate change issues.”