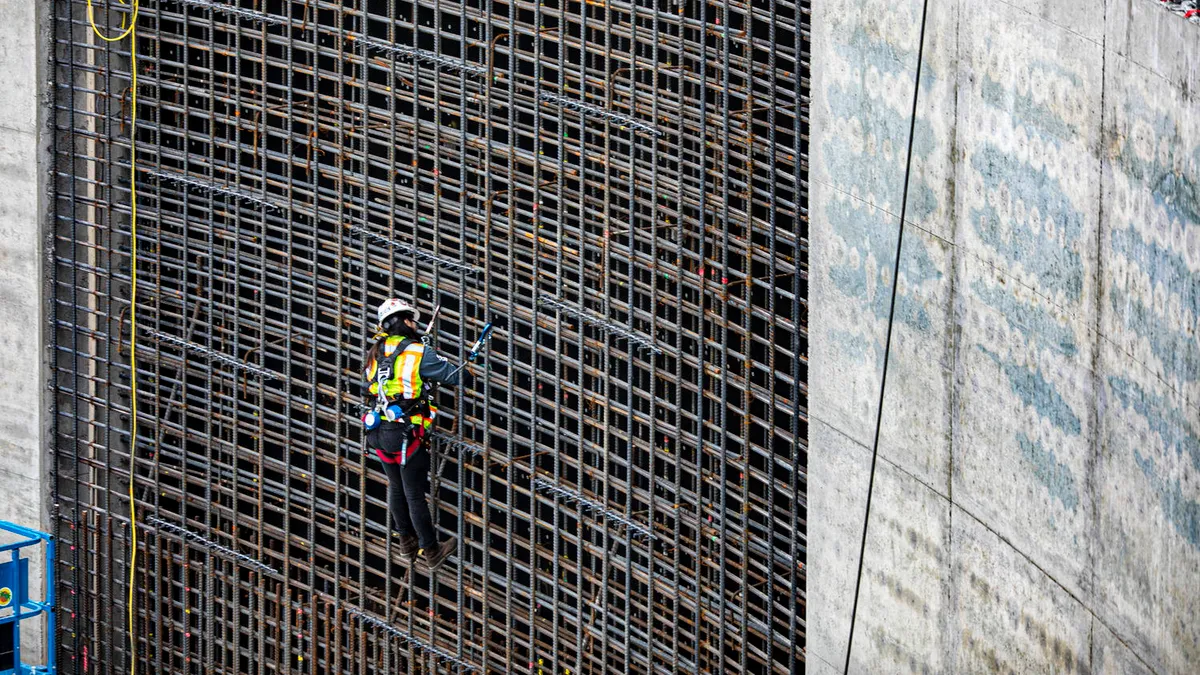

Construction managers don't have a silver bullet approach at their disposal to prevent onsite falls. Instead, protective gear needs to fit the unique scenarios and structural considerations for each specific jobsite, according to speakers at a recent webinar hosted by the Center for Construction Research and Training (CPWR).

The speakers included multiple members of the American National Standards Institute/American Society of Safety Professionals Z359.14 subcommittee that focuses on self-retracting devices for fall arrest and rescue systems

"A 'one-size' approach just doesn't accomplish the overall mission," said Adam Rubin, vice chair of the subcommittee and vice president of safety at Buckeye Partners, a Houston-based petroleum distributor. "The truth is, this doesn't exist, especially in a contracting space."

OSHA cites falls from elevation as the leading cause of death for construction employees, noting that these fatalities are preventable. Of the 1,008 construction fatalities in 2020, OSHA found 351 resulted from falls. The proper protective gear is crucial for decreasing onsite injuries and fatalities, OSHA says.

Updated standards and best practices

Webinar speakers detailed the updated fall protection and restraints standards, including requirements for self-retracting lanyards, that the ASSP published last year. The new standards take effect in August and provide guidance on the best safety gear and practices to prevent onsite falls and injuries.

All equipment manufacturers must increase the strength of their devices by at least 20% to meet the new updated standard for self-retracting devices. Contractors can phase in the new, more robust equipment as older versions wear out, while continuing daily and quarterly inspections to ensure the gear's integrity.

Both foreign- and domestic-made products should be checked for compliance with the updated standards, said Dan Henn, subcommittee vice chair and vice president of operations at Reliance Fall Protection, a Deer Park, Texas-based fall protection manufacturer. The only sure way to understand a product's compliance and if it fits within a company's fall protection program is to have a relationship with the manufacturer and ask for data, he added.

Personal protective equipment prevents serious injuries and fatalities but shouldn't be construction workers' first line of defense against falls, speakers said. In accordance with the hierarchy of controls for safety recommended by National Institute for Occupational Health and Safety , strong worker protection plans focus on incident prevention and involve five methods, in order of importance:

- Hazard elimination.

- Substitution.

- Engineering controls.

- Administrative controls.

- PPE.

"In a society where we've become very, very PPE-reliant, a lot of times we think that we're safe because we have the PPE," Henn said. "Just being tied off doesn't mean we're not going to get hurt or fall. So we really need to take a look at all the variables that are involved here."

Getting safety professionals involved early and incorporating safety practices and processes into project design helps to mitigate issues in the field. Examples include engineering tie-off points or rigid rail systems into the build of the structure.

Overcoming hurdles, facing dangers

Construction pros sometimes encounter resistance from fellow decision-makers when suggesting implementing or upgrading a hierarchy of control system, largely because people don't like change, Rubin said. Therefore, persistence is the name of the game, in addition to addressing obstacles.

"The first part of your conversation has to be getting past the change factor," Rubin said. "Once you get past the change factor, showing value for things, especially around fall protection, is relatively easy."

Self-retracting lanyards can save lives, but time is of the essence when rescuing a person suspended in a harness to avoid further injury. Sustained time dangling from a harness could induce suspension trauma, when pressure from the device causes blood pooling in veins and reduces circulation. The condition could result in loss of consciousness, organ failure or even death.

Suspension trauma can occur in as little as five minutes after a fall, according to the NIOSH. OSHA recommends removing a person from a suspended position as soon as possible, but certainly within 30 minutes. Performing a rescue sooner than 11 minutes post-fall is a widely understood industry standard, webinar panelists said.

Set expectations, routines

In addition, it’s vital to set clear expectations with employees and conduct year-round training and fall protection tests, rather than waiting for the annual Safety Stand-Down Week, panelists said.

Infrequent checks could force a construction company to contend with some awkward realizations, said Thom Kramer, principal and chair of the fall protection committee and managing partner at LJB, a Miamisburg, Ohio-based engineering firm.

"Are you good, or are you hoping that you're lucky?" he asked.

The most impactful safety plans include contingency plans for failures, said Mike Dickerson, committee member and safety consultant at Richardson, Texas-based American Contractors Insurance Group.

"You're working with humans and people are still going to still manage to make mistakes despite your best efforts," he said. "You have to account for that; that's why we're looking at more robust fall-arrest lanyards and equipment."