It’s a running joke with the builders working on the new Smithsonian museum project. The structure represents several building museums in one. The exterior, the systems, the intricacies of the building process — it’s all "one of a kind," according to the construction team.

Building the National Museum of African American History and Culture in Washington, DC, is a "once in a lifetime chance" for Brian Flegel, senior vice president with Clark Construction. Clark, along with Smoot Construction and H.J. Russell & Company, are serving as construction managers on the $540 million project, with their contract worth $400 million.

Related story: 20 photos inside the Smithsonian's new African American museum

The unique nature of the build stems from both the design and construction process, as well as the cultural significance of the museum, Flegel noted. The museum will open Sept. 24 with a ribbon cutting ceremony featuring President Barack Obama.

Flegel offered Construction Dive an inside look of the museum months before it opens to the public and detailed the building process, construction challenges and ultimate goal for the millions of visitors who walk through its halls.

Early stages

Decades in the making, the project started to become a reality when officials recommended the site near the Washington Monument, next to the National Museum of American History and 15th Street, in 2006. The project was funded by the Smithsonian and federal funds, and it marks the last available building site on the National Mall.

In 2008, the museum board launched a competition for the structure’s design. The winning selection came from Freelon Adjaye Bond/SmithGroup, a collaboration between four firms: The Freelon Group, Adjaye Associates, Davis Brody Bond and the SmithGroupJJR.

The Clark-Smoot-Russell team was then brought on to manage construction and broke ground in February 2012. Clark has extensive experience in museum construction, as it built the National Museum of the American Indian and National Law Enforcement Museum, and is currently building the Museum of the Bible.

The construction process

"It’s one thing to build a building, but we’re building a one of a kind building," Flegel said. "It’s one of a kind in terms of location, envelope, logistics and exhibit design."

With the museum's grand opening set for September, Obama — the nation’s first African American president — will still be in office to commemorate its debut. "The timing aspect was an obstacle," Flegel said. "The project almost looked like a fast-track build. We’d get the information just in time to build." Despite these obstacles, overall construction costs for the project have fallen within 5% of the guaranteed maximum price, according to Flegel.

He added that the project was more difficult than any previous museum project he worked on due to the accelerated schedule and the fact that construction began before the team had received the exhibit design or knew exactly which artifacts would be included.

Another challenge for the construction team emerged when the design for the museum was changed to push the structure even further into the ground and add more levels below grade. The museum is the deepest building in the National Mall, with excavators digging 70 feet below ground and the final structure eventually situated 65 feet below grade.

The fact that the majority of the structure is below ground complicated the building process, as 60% is below grade and only 40% is above grade, Flegel said. Visitors might not realize when strolling to the main entrance that they are walking on top of the museum below, as the 410,000-square-foot structure spans nearly the entire city block.

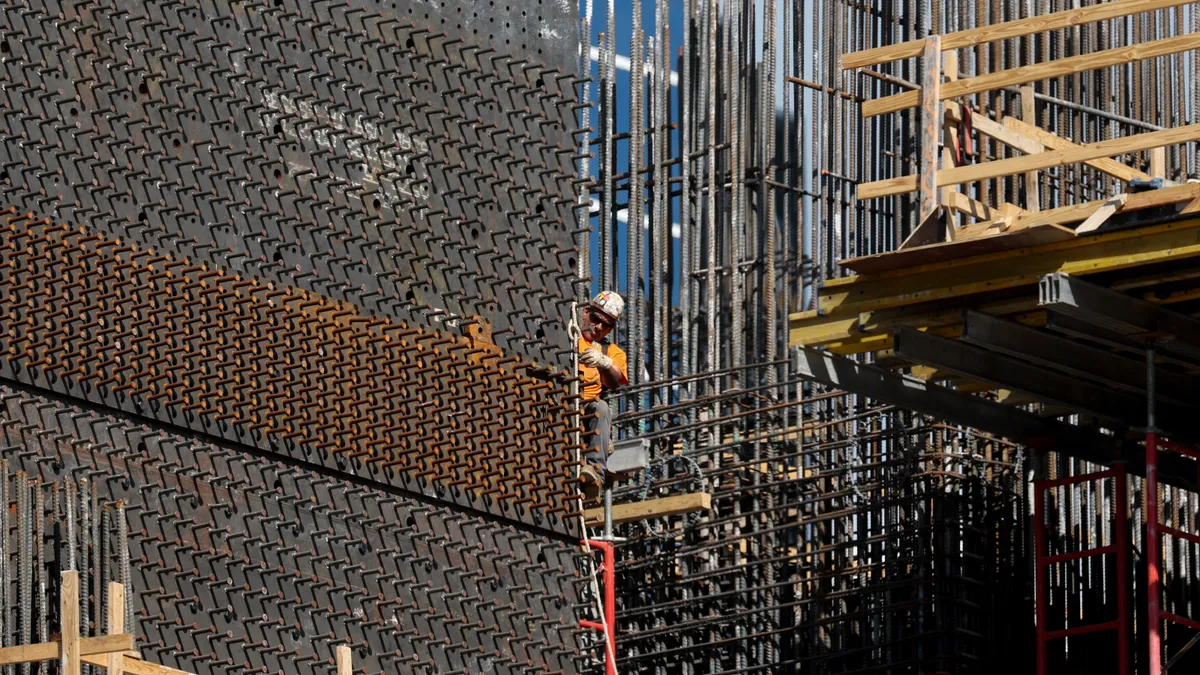

"We’re 65 feet below Constitution Avenue on a mat foundation with 39,000 pounds of pressure around the structure," Flegel said. He added that the walls are 6 ½ feet thick and that teams utilized #18 rebar — a level used for nuclear power plants.

The building features five levels above ground — including the ground floor — and four below. The construction team aims to achieve LEED Gold certification for the structure, and Flegel said he felt confident they would meet the standard.

The bottom floor includes all key components of the mechanical and engineering systems, as none of the systems are remote. Flegel called the process to include all necessary systems "one of the most intensive coordination efforts," as 40 coordinators worked together to design the arrangement. "To fit all these things into their place is complicated," Flegel said. He added that the construction team used Autodesk’s Revit to create 4-D models of the coordination beforehand, as Revit has "become the industry standard."

Bringing the design to life

Flegel called the building’s design "very unique" and said he had "never seen something like it." Freelon Adjaye Bond/SmithGroup designed the exterior to echo the "corona" — an African crown architectural form, according to the Smithsonian. Flegel added that the angle of the slanted exterior panels mirrors the angle of the top of the Washington Monument.

The exterior itself is "meant to be an exhibit," Flegel said. The structure’s sides feature curtain wall covered by metal panels. Determining how to create the complex corona exterior presented one of the project’s greatest challenges, but it is also the aspect of the building that Flegel said he is most proud to have built.

After adapting the original design’s assembly plans, the construction team landed on a special aluminum alloy for the panels that they believe created a "noble" look. Once the material was selected, project managers needed to determine what type of finish to use for the bronze appearance. Valspar worked with them to create a five-part system for painting the panels that offered the desired dimension in the design.

Flegel said it took more than a year to cast, paint and assemble the exterior panels onto frames. Once they were brought on site, a lifting mechanism lifted the frames to lock onto pins on the building. In total, it took workers approximately eight weeks to assemble the nearly 3,700 panels. "It was a great collaboration in tackling the first of its kind," Flegel said.

Outside of the building, a porch area features a 210-foot-long concrete overhang supported by columns on either side. The material for the structure is a thin, ultra high-performance concrete, which Flegel said is a fairly new product in the industry. The outdoor site will also include a water feature, and the exterior is surrounded by landscaped areas. The grassy area where visitors walk is also one of DC’s largest green roofs.

The visitor experience

The museum aims to offer visitors an experience and "tells a story" as they advance from the lowest level up to the top, Flegel said. At the starting point, attendees begin in Africa with the slave trade. The lowest level features a guard tower from Angola and the Jim Crow-era Pullman railroad car.

Installing the railroad car was another of the construction team’s biggest challenges, as the builders had to shut down two surrounding streets to bring in the 80,000-pound artifact. Despite detecting an engineering error at the last minute, crews were able to install the car in November 2013.

As visitors ascend through the museum, the story evolves to reflect African Americans’ progress achieving freedom and their impact on U.S. culture. The below ground levels guide visitors through slavery, segregation and present day. When visitors reach the level just below ground, they can enter the "Contemplative Court" — a small room with a central water feature that offers the opportunity to pause and reflect.

Throughout the museum, builders used acoustical plaster to create a quieter experience for visitors. The color scheme includes mostly earth tones, rather than a "splashy" color palette, Flegel said.

The first level below ground also includes the Oprah Winfrey Theater, which officials announced in 2013 they would dedicate after Winfrey donated $12 million to the museum. The theater is isolated acoustically and includes wall designs that echo the corona design on the building’s exterior. The 350-seat space will be available for shows, demonstrations and film viewings.

The museum’s main entrance and Central Hall are located on the ground floor and feature floor-to-ceiling windows offering expansive views of the surrounding National Mall. The levels above ground include education space as well as sports and cultural exhibits, which highlight African American icons.

Looking to the finish line

Flegel said he is confident that construction will wrap up in time for September’s grand opening. Although plenty of final touches remain inside the structure — including the Smithsonian’s installation of more than 30,000 artifacts — construction is starting to wind down.

Flegel views the project with pride, as he called it "a pretty aggressive adventure that has worked out pretty well." He added, "I love the creation of the spaces. I love that the museum tells a story."