As spring construction season begins, staying on top of new tech trends is important to builders looking to maximize output and slash costs. Here are five recent announcements from software makers and other tech providers about new offerings or updates to existing products that are designed to smooth out construction for contractors:

Leica Geosystems

Positioning and sensor specialty firm Leica, part of Stockholm-based digital reality company Hexagon, has partnered with heavy equipment maker John Deere. Leica’s technology will now sit inside Deere’s SmartGrade 3D grade control system, a combination the two firms say will allow builders to improve efficiency and reduce material costs and the number of passes required to grade a jobsite. That last benefit should also translate into safety gains, according to the companies, by reducing traffic on construction sites.

"Together, we will bring new levels of accuracy, productivity and accelerate the implementation of safe and sustainable workflows to the construction industry,” said Troy Dahlin, Leica’s vice president of heavy construction in the U.S. and Canada, in the release. Leica’s technology will be available on select John Deere equipment later this year.

Matterport

Digital twin creator Matterport, which scans structures to create as-built renditions of projects that can be viewed remotely, announced several enhanced capabilities of its products this winter.

The firm’s new Property Intelligence features use spatial data, computer vision and deep learning to automatically calculate square footage, including dimensions of walls and ceiling heights from a scanned space. Matterport said that’s a big time saver, as contractors can spend up to 10 hours manually measuring and labeling elements within a 3D model.

The company’s Compass and Minimap plugins also give contractors a leg up working on a project by allowing viewers to navigate large spaces. The tools provide a POV, immersive rendition of a space, complete with a small map inset in the upper corner, while indicating which direction is north relative to the user’s viewpoint. That’s particularly useful to construction and development teams, according to the release, for understanding elements like daylight, wind and other factors that can impact a space.

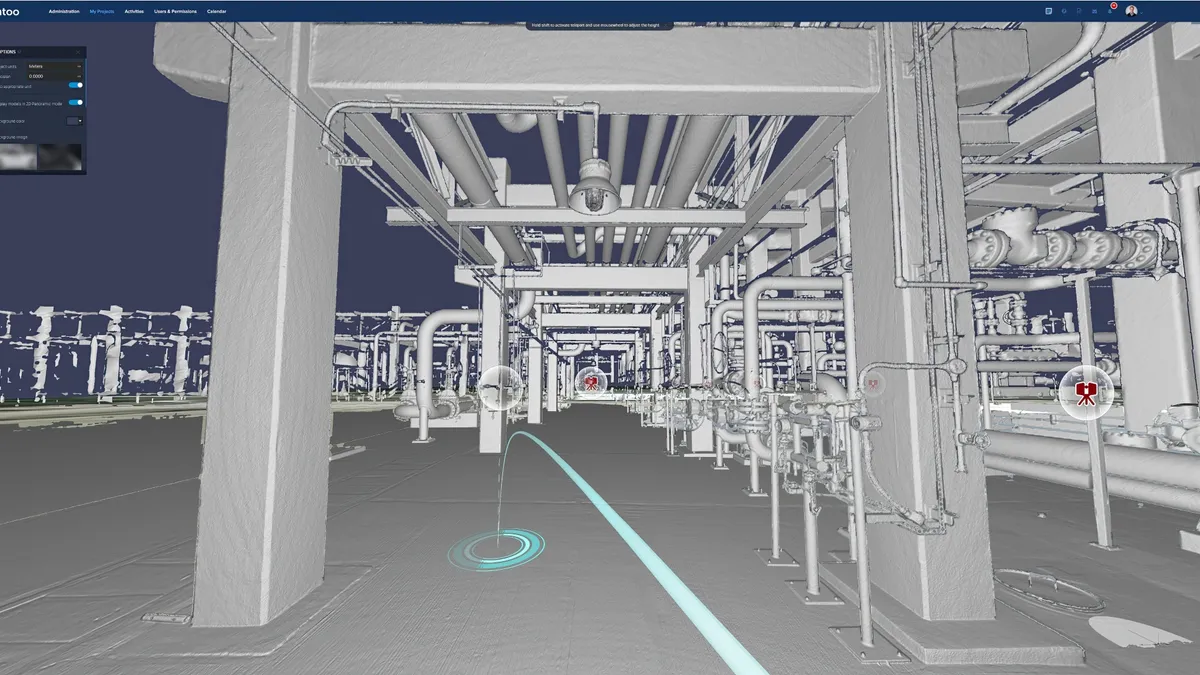

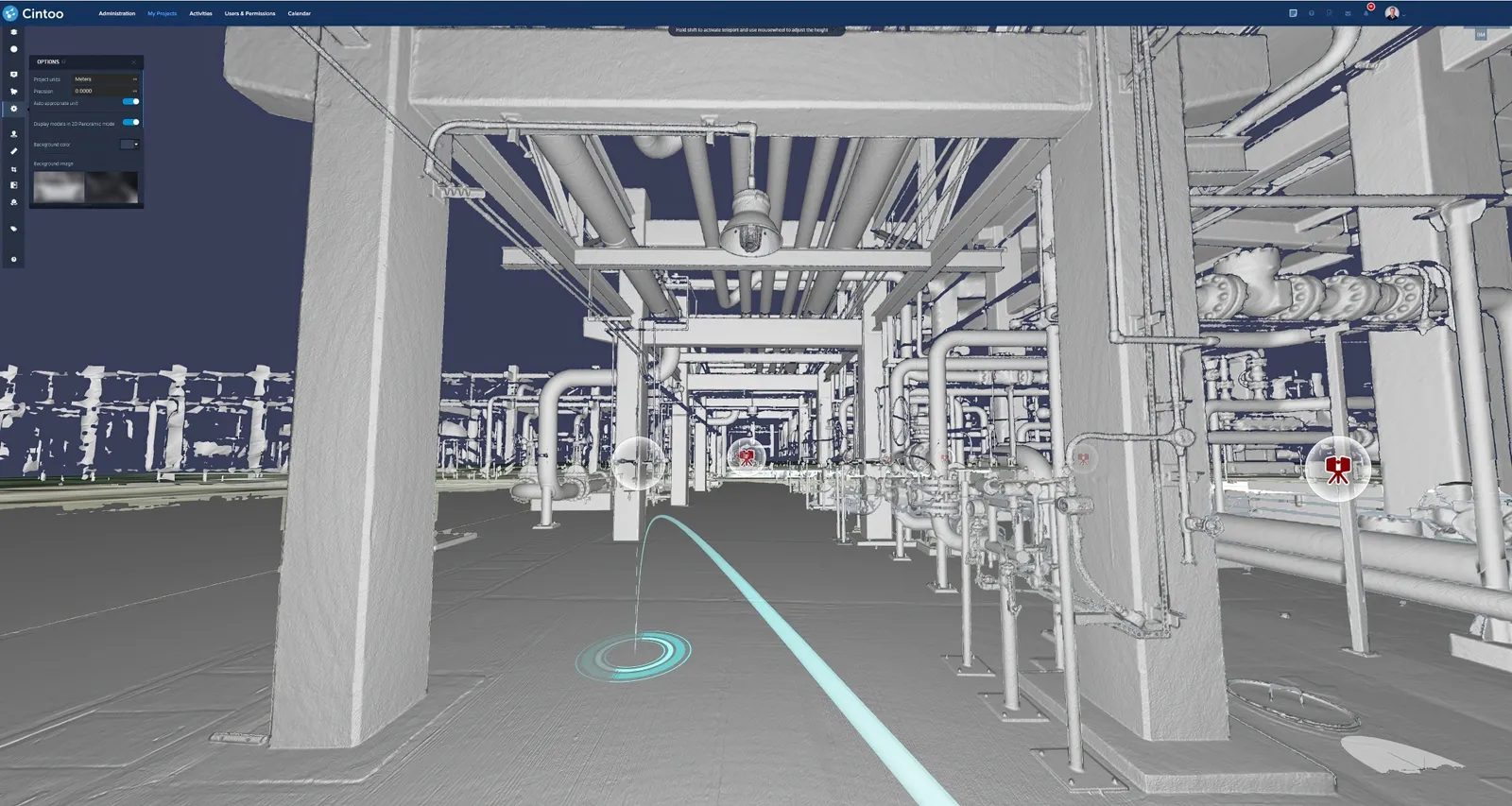

Cintoo

One of the challenges of navigating a 3D point cloud built from numerous 3D data points is that many users become dizzy while engaging in virtual walkthroughs.

Miami-based Cintoo says it has solved this issue with its new “teleport camera,” which allows users to walk through scan data by creating an unlimited number of panoramic virtual vantage points that complement the laser-scanned data captured for panoramas. The result is similar to using a video game, which means non-expert users like owners and customers can see projects take shape without experiencing vertigo.

“We believe that the trustful, but expensive, laser scan data should be used by many, many more people that are not expert surveyors or VDC engineers,” said Cintoo CEO Dominique Pouliquen in the news release. “Cintoo has now gamified the use of laser scans to all users to maneuver to any position and point of view within the reality data with no prior 3D expertise.”

IDS GeoRadar

Pisa, Italy-based radar solutions provider IDS GeoRadar, a Hexagon company, unveiled its latest concrete scanning solutions earlier this year. The new tools empower construction teams to scan concrete structures efficiently, detect elements deeper beneath the surface and make informed decisions about where to cut or drill safely, according to the release.

Weighing less than half a kilogram, the C-thrue XS is a handheld ground-penetrating radar scanner for concrete inspection that is designed for use in hard-to-reach areas. Its dual-polarization capability allows the scanner to send and receive signals in both horizontal and vertical orientations, ensuring more accurate and detailed results, the firm said.

NDT Reveal, an integrated software solution for analyzing and managing subsurface data, allows users to manage GPR data analysis and reporting in one place, helping to optimize the workflows of large, complex projects, the company said. Users can also upload collateral information such as photos, site sketches and CAD drawings, and make them accessible to all team members.

SafeAI

Santa Clara, California-based autonomous heavy equipment retrofitter SafeAI and Japanese construction company Obayashi Corp. recently unveiled a retrofit zero-emission, autonomous haul truck. The Caterpillar 725 is the first haul truck retrofitted with autonomous and electrification technology, according to the release, paving the way for companies to reuse existing assets while improving operations and enabling them to reach their sustainability goals.

This combination of automation and electrification affords several advantages that are otherwise hard to achieve as independent technologies, the release said. For instance, autonomy alone can boost environmental performance on worksites by up to 13%, and by swapping out diesel for electricity, operators can cut net life cycle emissions by over 60%, according to the company.

“In addition to demonstrating the synergy between autonomous and electric technologies, we’re also excited about the retrofit aspect of this project,” said Sugiura Shinya, Business Innovation Division general manager of Obayashi. “A retrofit approach allows contractors to proactively upgrade their vehicles to advance carbon neutral strategies.”