Dive Brief:

- Salt Lake City, Utah-based Sarcos Technology and Robotics completed a field trial of its robots on a Mortenson solar project, the tech company announced on March 8. JLG Industries, Array Technologies and Pratt Miller also collaborated on the test.

- The trial, which Sarcos dubbed its Outdoor Autonomous Manipulation of Photovoltaic Panels project or O-AMPP, was the final milestone of a $1.9 million Department of Energy contract that was awarded to RE2 Robotics in 2021. Sarcos acquired RE2 Robotics in March 2022.

- Jorgen Pedersen, Sarcos’ chief operating officer, told Construction Dive that the company has a few more field trials planned, and is shooting for commercial availability of the product in 2024.

Dive Insight:

Pederson said solar installations were one of the company’s top priorities due to what he called an “acute need for innovative solutions.”

Mortenson Vice President of Industrialization Trent Mostaert, who coordinated the project, said the technology comes at a time when demand is spiking in the solar sector.

“The solar construction industry is facing unprecedented labor shortages while simultaneously facing an increase in demand for solar energy,” Mostaert said in the release. “We believe the O-AMPP system can address these challenges while improving safety, productivity and efficiency for our workers.”

Indeed, according to the Solar Energy Industries Association, annual solar installations will need to increase by 60% to meet the 2030 climate goals of President Joe Biden’s administration. Doing so would take an additional 900,000 workers, according to the group.

The technology that Sarcos tested included the Guardian XM, a robotic arm that can manipulate heavy pieces of equipment and eliminates the need for humans to move weighty, awkward objects.

That’s useful for handling commercial solar panels, which can measure more than 6 feet by 3 feet and weigh around 50 pounds each.

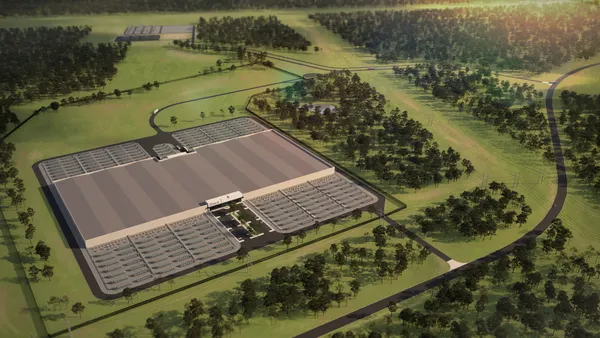

For context, Mostaert said the entire project had 204,000 modules installed overall.

The majority of those panels were still placed by people. But to test the robots, Mortenson intentionally left one row of trackers, or the frames the solar panels are mounted on, incomplete, without the solar panels on top.

Then, Mortenson, Sarcos and the rest of the project team used the robot’s arm, outfitted with suction cups, to lift the remaining solar modules in place. Workers performed the final attachments.

Mostaert said the project, which ran from April through December 2022, was “a good proof of concept” and that Mortenson would be looking for opportunities to add robots to their solar jobs in the future. He noted the system still needs more fine tuning before it can become fully commercially viable.

“Over time, as the technology gets better, our hope is to continue to modify and get the machines to run smoother and quicker,” Mostaert told Construction Dive, adding that his firm would continue to look for opportunities to include machines on solar jobsites.