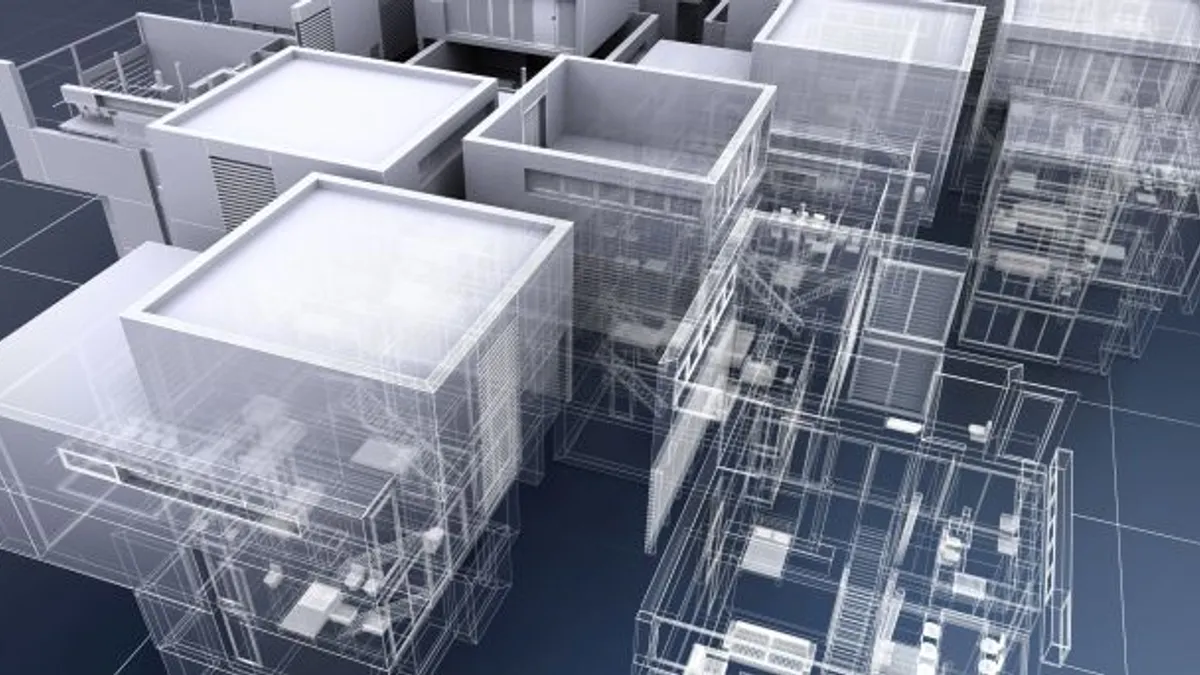

While mechanical contractors are sophisticated users of BIM software, their ability to fully leverage modeling technology is hampered by the need for training and skilled manpower among other issues, a new study has found.

“All of our BIM research over the last 12 years has consistently shown that mechanical and HVAC contractors have been very enthusiastic adopters of BIM and are very aggressive at increasing their implementation level once they get started with it,” said Steve Jones, senior director of industry insights at Dodge Data & Analytics, which led the study entitled “The Business Value of BIM for Mechanical and HVAC Construction.”

It found that 90% or more of the mechanical and HVAC contractors who work with BIM are providing a model of their work on at least some, if not all, of their projects on which BIM is being deployed, he told Construction Dive. And they have many reasons for doing so, including for spatial coordination and constructability evaluation.

“They can address issues before construction begins, which saves both time and money and can even help improve safety by avoiding rework,” Jones said.

Nevertheless, there are still challenges that prevent these contractors from fully leveraging the use of BIM, including training for employees and a lack of available manpower to create BIM models. In addition, contractors struggle to fully engage with BIM across the project team, with lack of support for BIM from other important trades, the issue of other stakeholders on their projects not using BIM, and poor quality BIM use by other stakeholders also presenting significant challenges.

On-the-job training

At San Jose, California-based electrical contractor Rosendin Electric, BIM adoption has been steadily increasing, especially for high-stakes, large and complex projects, said Fred Meeske, Rosendin vice president of BIM technology services. Like many specialty contractors, Rosendin has some limitations with lack of modeling resources and employee knowledge about BIM.

To overcome this challenge, the company has created a robust assessment and retraining system to assess new employees. If the applicant has prior modeling knowledge or is deemed to have the necessary skills to learn modeling software, a personally tailored training program is created, Meeske said. Furthermore, all Rosendin staff that use modeling go through a similar assessment once a year.

“This allows Rosendin to identify opportunities for improvement among its existing employees, especially when new software or processes are implemented, and tailor personal training programs,” he said.

Prefab processes

One of the biggest benefits of BIM reported by contractors is its ability to improve the fabrication process. Many mechanical contractors are frequent users of offsite fabrication for their systems, and the study shows that nearly half use BIM on 50% or more of the assemblies they prefabricate.

“The measured benefits of using BIM often outweigh the costs, making it simply the correct choice to use BIM even when not required."

Jad Chalhoub

BIM lead, Rosendin

Benefits from using BIM to aid prefabrication were widely reported, with over 80% of mechanical contractors who use it to prefabricate reporting that they see improvements in the material waste generated, labor costs, quality of installed work, avoiding the purchase of extra pipes and fittings and schedule performance.

Other top benefits reported by contractors using BIM in general are increased labor productivity, increased profitability, better utilization of resources and improved cost performance. By using BIM, mechanical contractors have also been able to leverage the technology to conduct more analysis on their projects.

Taking the lead

Rather than waiting for GCs to request it, contractors often manage BIM projects, especially for complex mechanical work, according to Sean McGuire, director of innovative technologies at the Mechanical Contractors Association of America, one of the sponsors of the study.

“As far as mechanical contractors go, they often take the lead on BIM projects due to the complexity, the coordination of pieces and the design change required between what they get from the engineers and what they design and build to make systems work,” he said. “They also tend to have a part in many of the clashes that need to be resolved.”

BIM is being contractually required more than ever before by general contractors, according to Jad Chalhoub, technologies solutions implementation lead at Rosendin. Even without this requirement, Rosendin would still move toward BIM adoption, he said.

“The measured benefits of using BIM often outweigh the costs, making it simply the correct choice to use BIM even when not required,” he said.