Dive Brief:

-

A new report from the McKinsey Global Institute estimates that machine automation could result in annual global business productivity gains of 0.8 to 1.4%.

-

Leveraging automation to simplify individual tasks, versus replacing entire job classes, is a central facet of realizing efficiency and productivity gains from machine automation as less than 5% jobs are candidates for full automation, according to the report.

-

Roughly half of all global workforce activities could be automated using currently available technology, the report finds, generating $15 trillion in wage savings alone.

Dive Insight:

It looks like the rise of the machines won’t happen as quickly or comprehensively as expected. While McKinsey’s report argues for broad adoption of automation, its authors are quick to point out — and even advocate for — the increased role of human interaction with technology to meet productivity gains and realize future innovations.

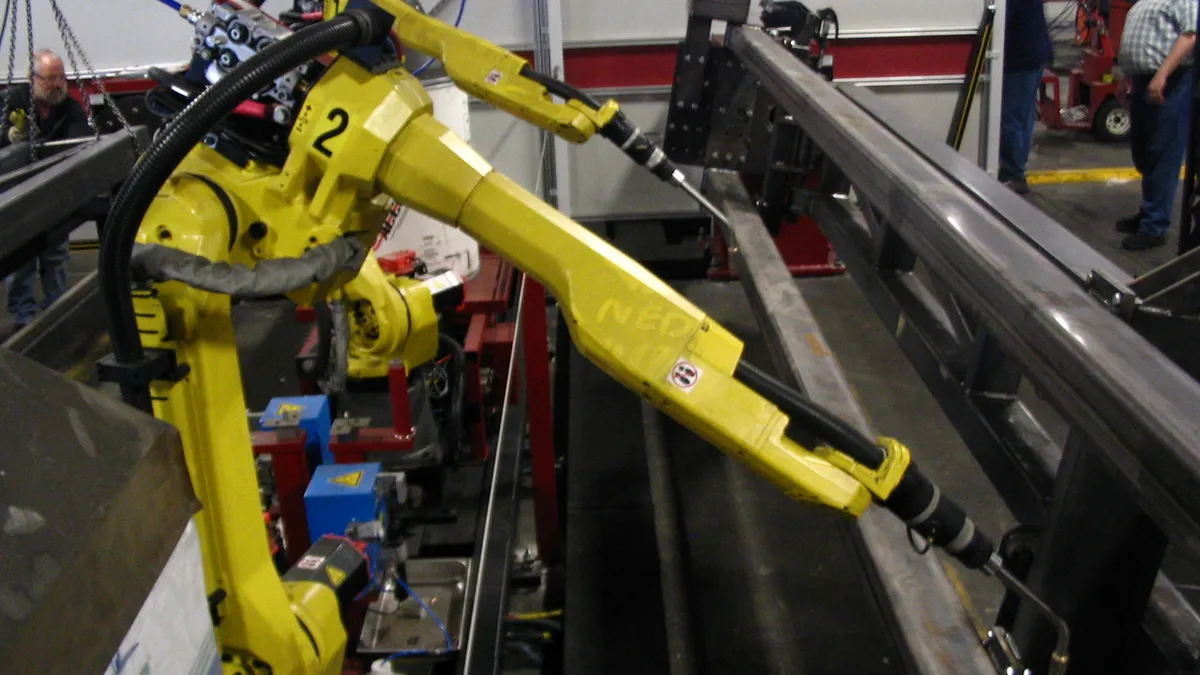

Following that strategy, the U.S. alone could realize $2.7 trillion in wage savings by automating data collection, processing and (critical to the AEC sector) tasks requiring physical labor. That said, the authors indicate that automation works best in environments that are structured and highly predictable, noting manufacturing and food-service as primary examples.

Indeed, the continually changing nature of the construction job site has most heavy-equipment automation efforts focused on over-the-road applications. “There are many unknowns challenging full automation in construction,” Willy Schacks, president of construction equipment telematics firm EquipmentShare, told Construction Dive. “Construction is an unpredictable environment that is constantly changing. You can start with automating repetitive movements, but until [artificial intelligence] advances far enough to compete with the human brain in reacting to unknown and suddenly changing environments, there will always be a human element guiding job site equipment.”