Dive Brief:

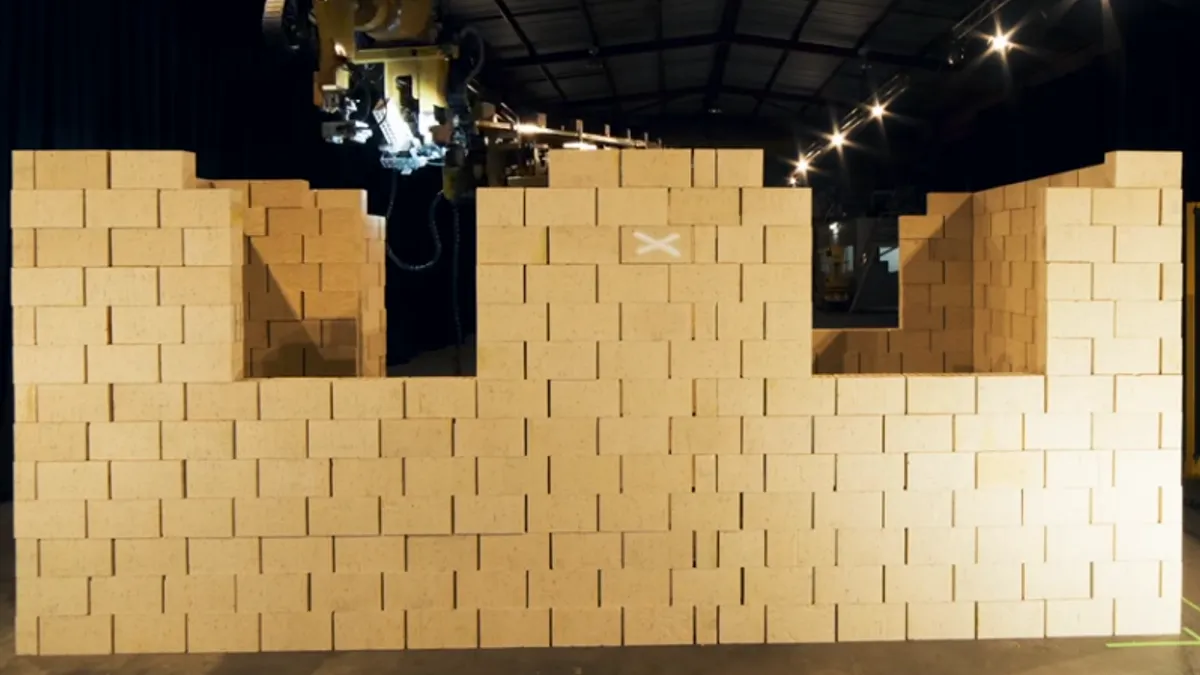

- Australia's Fastbrick Robotics is showing off its Hadrian 105 automated bricklayer, which the company said can lay 225 bricks per hour, resulting in a finished shell in a quarter of the time it would take a human to build one, according to 3DPrint.com.

- Using a CAD model, the bricklayer places courses of bricks, including cutting and routing, via laser guide. A recent time-lapse video of the robot has drawn major internet attention, as it currently has more than 200,000 views on YouTube.

- Fastbrick said its next model, Hadrian X, is truck-mounted and will be able to lay 1,000 bricks per hour.

Dive Insight:

According to Fastbrick, Hadrian X will deliver the added convenience of transporting all the brick materials to the job site. Construction Dive first reported on Fastbrick's Hadrian line of robotic bricklayers last year. At the time, Fastbrick CEO Mike Pivac told Gizmag that inventions like his could help alleviate the shortage of skilled construction workers.

While the company tags its bricklayers as 3-D because of their additive qualities, the technology is not one people usually associate with the latest line of 3-D-printing advancements, as the bricklayers aren't actually creating the brick or extruding any material used in the placement process. This is unlike homebuilding 3-D printers such as BAM Group's freeform "3D Builder," which can navigate a job site on its own and uses different print-head assemblies to print concrete and stone structures.

Another freeform 3-D process comes from Tennessee's Branch Technology, which has developed a cellular fabrication system called "C-Fab." The company uses robotics to cover scaffolding forms with spray foam concrete and stucco, turning them into walls. Branch recently announced the winner of its first design challenge, which involved designing a single-family home that will utilize the C-Fab technology during construction.

It's taken a while for 3-D-printing to begin to fulfill its promise, but the industry is finally starting to see some real-life, practical applications backing up the hype. Dubai offers up a prime example of this shift with the first 3-D-printed office building in the world. It took builders only 17 days to 3-D print the 2,000-square-foot building, which also includes 3-D-printed furniture. The builders used a 20-foot high, 120-foot long and 40-foot wide 3-D printer with a robotic arm to place reinforced concrete, glass-fiber-reinforced gypsum and fiber-reinforced plastic. The office building was the country's first completed project after announcing that 25% of all the city's buildings will be 3-D-printed by 2030.