Dive Brief:

- The construction industry isn’t taking full advantage of new technologies for workflow management and building performance monitoring, including advanced data and analytics, automation, robotics and mobility, according to consulting firm KPMG’s annual report, "Building a technology advantage — Global Construction Survey 2016."

- Two-thirds of the 200-plus construction and engineering executives and major-project owners surveyed said they don’t use advanced data analytics to monitor project-related estimation and performance.

- Meanwhile, while project-related risk is increasing, fewer than 20% of respondents said they are rethinking their business models to incorporate new technology in response.

Dive Insight:

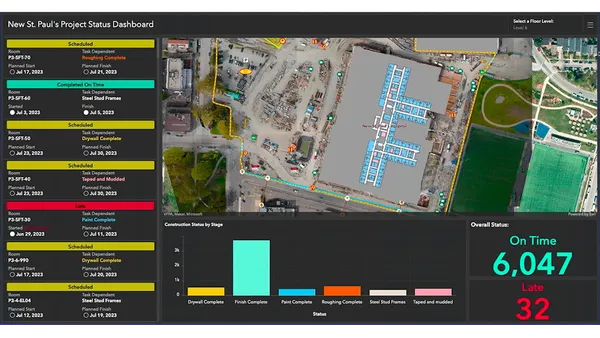

Although the construction industry is well-positioned for technological disruption, a mindset shift among practitioners remains the biggest challenge. In its survey, KPMG found that most construction firms are waiting for competitors to take the first step toward the adoption of technologies to streamline their workflows and improve their data collection — including integrated project management information systems, earned value management, remote monitoring, smart sensors, and robotics and automation.

Yet even the simplest commercial building project today requires a multitude of non-integrated software programs connecting stakeholders. And as projects become larger and more complex — consider the forthcoming $500 million Gramercy District "smart city" in Virginia and the expansive $3 billion Los Angeles Rams football stadium and entertainment district — precision and speed of information delivery and data collection are essential.

What’s holding the industry back from taking on tech? Cost, scale, and a lack of existing-use cases are a few of the factors keeping construction executives from investing in new technology.

One example is the promise of small unmanned aerial vehicles, or drones, hovering over job sites for tasks such as aerial photography, site monitoring, and even material transportation. A lack of clear regulations has kept many AEC firms from formally incorporating the equipment into their workflow, but those that have used the technology experimentally have confirmed its game-changing potential. Last month, the Federal Aviation Authority put its much-anticipated commercial drone rules into effect, giving businesses clear guidelines on how they could and couldn’t use the technology for commercial purposes. Four in 10 respondents to KPGM’s report said they have used drones to monitor the progress of a job.

Getting augmented and virtual reality technology into the field will likely face similar challenges. The tools offer significant potential for safety training and concept design, but concerns remain around the practicality of putting on an AR or VR headset and walking around a job site — particularly one that’s unfinished.