Dive Brief:

- Design, manufacturing and construction company Katerra announced this month that it will build a 577,000-square-foot-factory in Tracy, California, near the company's Menlo Park headquarters.

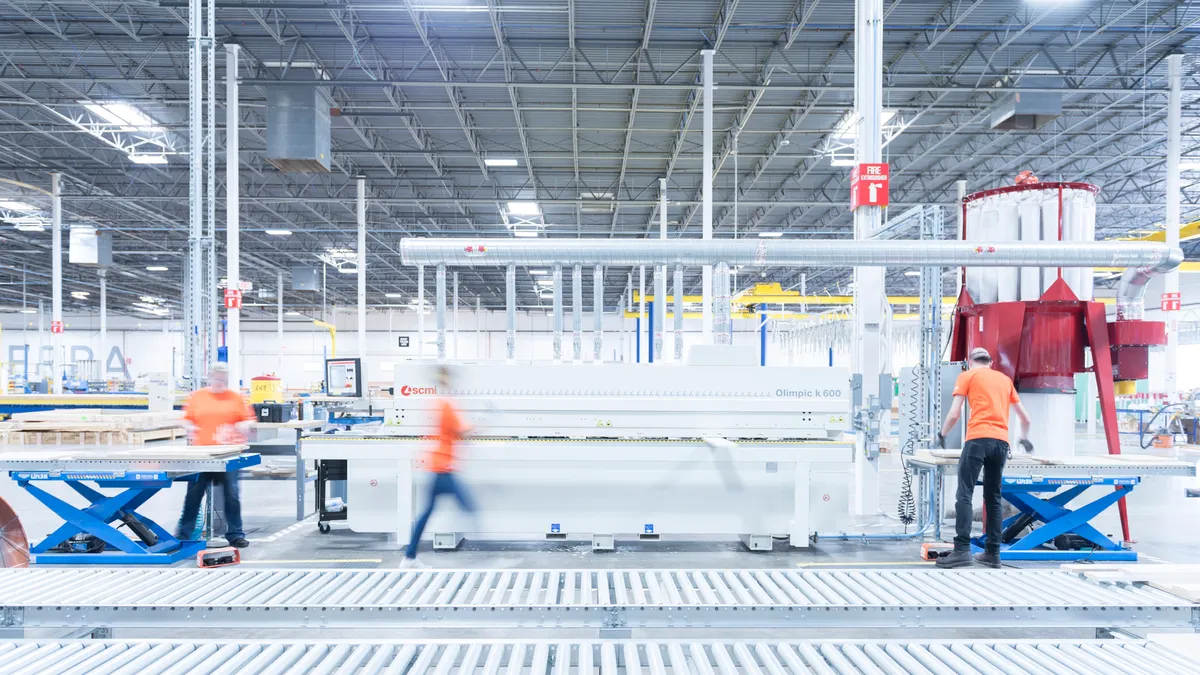

- Katerra said the "next generation" factory in Tracy will use more automation and technology than its Phoenix plant and will feature production lines for wood frame wall assemblies, floors, cabinets and finishes, roof truss systems, windows and light gauge steel. According to the company, the factory will have capacity to deliver the equivalent of 12,500 multifamily units annually.

- Katerra will tap the area's workforce to operate the factory's robotic equipment and expects to create 500 jobs in San Joaquin County, which suffers from a high rate of unemployment. The company said the plant will be located near rail, shipping ports and highways and that production should begin in 2019.

Dive Insight:

In March, Katerra announced plans to expand its manufacturing operations and open six new plants by March 2019. At the time, the plan was to open a mass timber factory in the Southeast and wood panel and truss plants in addition to a 250,000-square-foot mass timber plant in Spokane, Washington. When operational, the Spokane plant should produce almost 5 million cubic feet of cross-laminated timber annually.

Katerra has also been making industry waves with its mergers and acquisitions strategy. In June, the company acquired two architecture firms in two weeks — Michael Green Architecture in Portland, Oregon, and Lord Aeck Sargent, in Atlanta, Georgia. After the transactions were complete, Katerra saw its workforce double, and its licensing capacity increase to 31 states and Canada's British Columbia and Alberta provinces.

Also in June, Katerra announced a merger with Indian manufacturing technology company KEF Infra. The newly formed company of KEF Katerra has already generated $3.7 billion in new business and will focus its attention on projects like hospitals and schools.

Katerra's focus on offsite construction is part of a trend that has seen contractors try to increase efficiency, speed up the schedule through parallel and preconstruction and combat the labor shortage. Manufacturing building components in a factory setting also brings construction down to ground level, all but eliminating employee exposure to falls. The quality of work can also improve as workers focus on one element, gaining expertise, increasing productivity and giving the construction industry a taste of the automation that has revolutionized other industries.