Swinerton is a San Francisco-based commercial contracting company that does most of its work in the Southwest. To learn more about how the company uses technology to communicate with clients and its jobsites, Construction Dive spoke with Paul Nielsen, operations manager for Swinerton in Atlanta, to find out what innovations Swinerton employs.

Quoting app

Nielsen described Swinerton’s customized app, Hunch, as a response to the many times employees received a simple “napkin sketch” from clients, architects or owners and would be asked to provide an accurate quote for how much the project would cost.

“Rather than giving them a ballpark of cost per square footage, the way that this app works is that we enter in information that we know about the project, size, location, et cetera,” Nielsen said.

Hunch allows Swinerton to take its clients through 16 steps to determine the various options and costs associated with them based on Swinerton’s data. Everything from the number of offices, conference spaces, and specific plumbing and lighting fixtures can be determined through the app to provide an accurate estimate directly to the customer. Nielsen said they’re often working on a tablet with the client looking over their shoulder.

“What I love so much about this is we use it to be as interactive as possible,” Nielsen said. “It helps us to develop this relationship with the design firm, broker or client, get them in front of those people in advance and gives us a step ahead of what our competition may be able to bring to the table.”

The app is already a key part of the construction process for Swinerton, Nielsen said, and updates are on the way, including potential use for mass timber, multifamily and other specific markets.

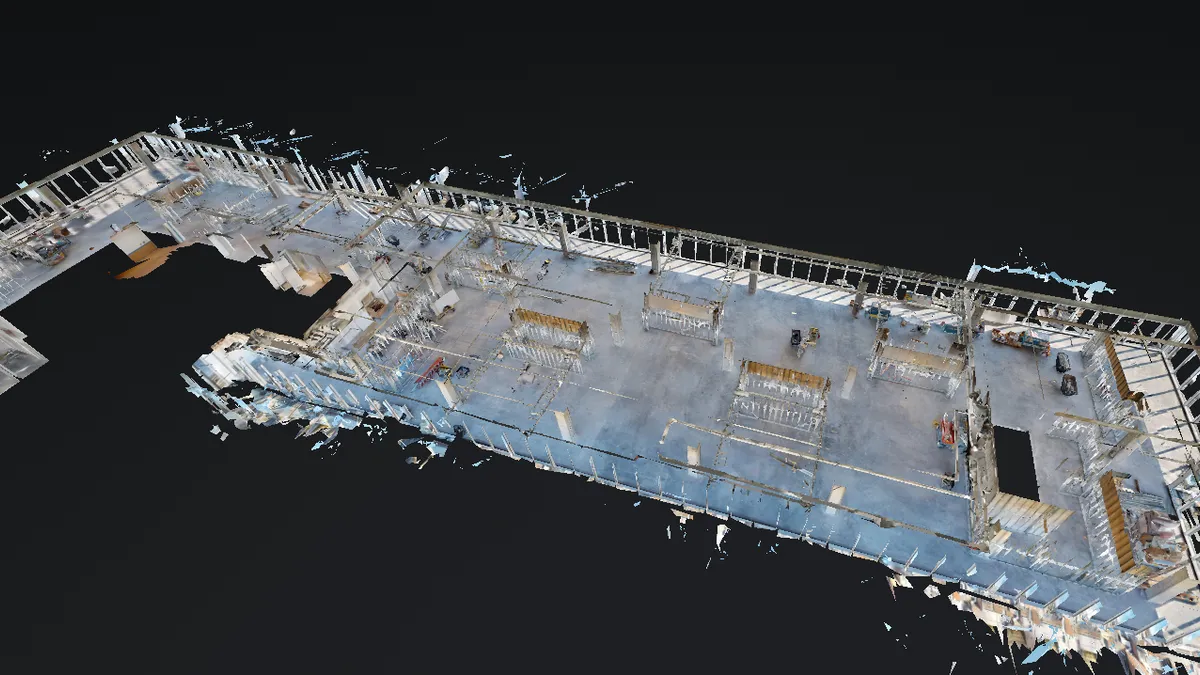

3D room-scanning technology

Primarily in the Southeast, Swinerton has implemented high-definition 3D image capturing for its jobsite work. The images are then time-stamped and put together, and, according to Nielsen, within 48 hours the company has an up-to-date “walkthrough” that can be viewed via phone, tablet, laptop or virtual reality goggles.

The 3D scanning is primarily for the interior of the project, to give clients a better idea of the layout and its progression. Nielsen said at this point the tech doesn’t aid much with the exterior of a building.

The Swinerton official said the 3D virtual walkthroughs are most beneficial for hospital and healthcare projects, as clients can see all of the uncovered piping and wiring in a documented and time-stamped fashion, to ensure accuracy and avoid mistakes.

Virtual walkthroughs also allow for an expanded client base to have easier access to projects, Nielsen said. On one project in particular, Swinerton used the 3D imaging to share virtual walkthroughs of a project in Atlanta with a client in Colorado. That saved time and money for both sides, and allowed the client to have a grasp on the project’s progress.

In the future, Nielsen said he wouldn’t be surprised if 3D walkthroughs like the ones Swinerton offers would allow for inspectors to make a virtual inspection of a project, if other circumstances prevented an in-person inspection.

Robot image capture

Boston Dynamics markets its Spot the Robot Dog to the construction industry as an autonomous vehicle designed to use an image-capturing payload. Since January, Spot has been used by Swinerton — which was selected as one of a handful of contractors as an early adopter by Boston Dynamics — on projects in Hawaii, Texas and California, and the contractor has plans to use the robot on other projects in the near future.

Thus far, the contractor has used the robot to reduce human error in image capture, maintain consistent information, conduct image capture and lidar scans on sites with fewer people and ease the regular scheduling of the captures.

Nielsen said the company is continuing to evaluate if the robot is worth the investment in the long term. Both companies did not disclosed the price of the robot.