Just 11 miles from the famous Hawaii-blue surf break of Waikiki Beach, water visibility in Pearl Harbor rarely gets beyond 8 feet. On the east end of Ford Island, the super-dreadnought battleship USS Arizona rests in silty water ranging from 1-and-a-half-foot-deep near the stern to 40-feet-deep at the bow. Registered as a historical landmark in 1989, the USS Arizona Memorial sees 4,500 visitors a day and is a U.S. military cemetery for the 1,102 sailors and Marines killed on the ship during the Japanese attack on Dec. 7, 1941.

In 2013, the National Park Service embarked on an effort to create a baseline structural data set for both USS Arizona and the Alfred Preis-designed memorial building that has straddled the wreck since 1962, with utmost attention to the solemnity of the site and zero closures. The final team — including specialists from over a dozen underwater and construction technology firms — worked with the NPS, the U.S. Coast Guard, a U.S. Navy Mobile Diving Salvage Unit and Woods Hole Oceanographic Institute for more than two years to complete reality capture.

"The idea was to build a data survey that all subsequent surveys could be measured against," said Pete Kelsey a strategic projects executive at Autodesk who served as team project manager and diver for the operation. "It was really all about change detection for this 100-year-old steel battleship that’s been underwater for 75 years in a very dynamic environment of salt water, corrosion, and coral growth — not to mention that it’s a war grave with 900 people in the ship who never got out."

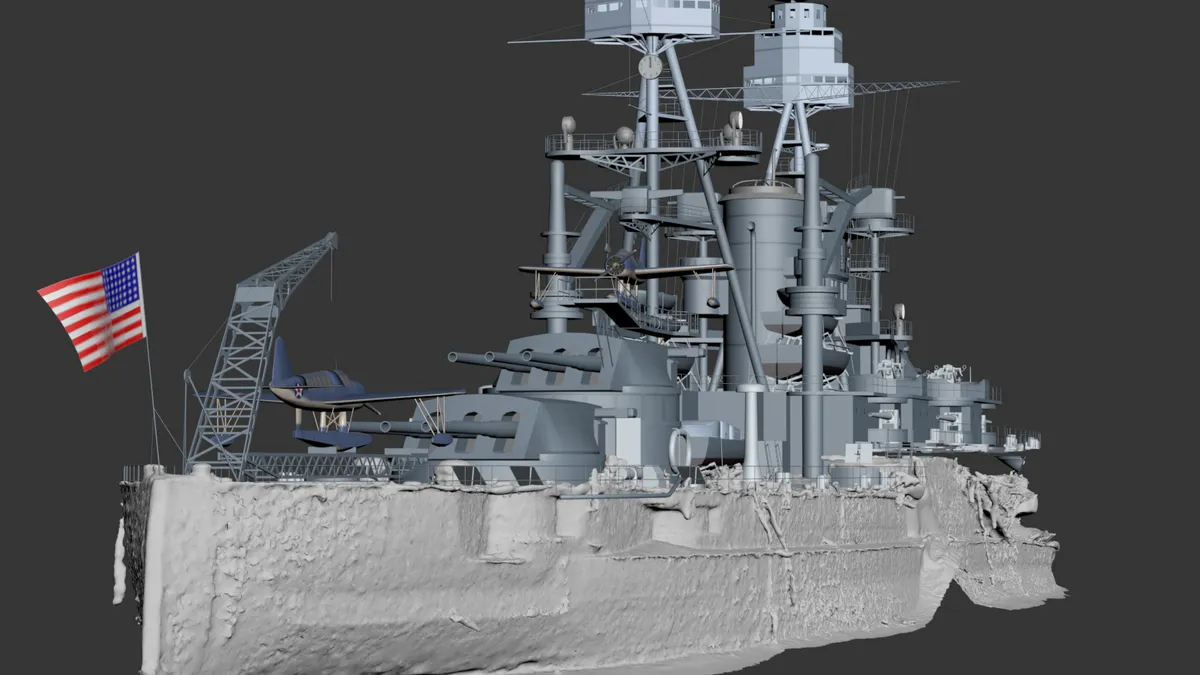

Completed in December 2016, the final data set marks one of the first maritime reality captures and combines information gathered during an initial survey in 2014 and a supplemental pass in August 2016, both of which mesh data collected with three different sonar systems, two separate LiDAR units, an RTK GPS survey and photogrammetry. The data set can be accessed using Autodesk systems including ReCap as a point cloud for actual survey and change detection, ReMake as a solid model for visualization, simulation, and analysis, and Infraworks as a contextual model for outreach and education.

Not only a seminal project in legacy preservation (NPS lauded the effort as a near-impossible technological achievement), the USS Arizona scan has also quickly emerged as a proof of concept for the successful application of terrestrial construction technologies to maritime environments — and that has futurists with an eye on sea-level-threatened-infrastructure taking note.

Marine machine learning

Jonathan Knowles is a member of the board of trustees for the SETI Institute, an adviser to NASA, and as explorer-in-residence for Autodesk, he is charged with conceptualizing science and tech opportunities likely to emerge in the next 10 to 100 years. "Our job isn’t to say here are the products we are going to need in 50 years, but to look at very long-term forward domains we think are growing in significance and to start doing some applied innovation in those categories," Knowles told Construction Dive via phone from the Frontier Development Lab at NASA’s Ames Research Center in California.

Increasingly, the forward domain commanding Knowles’ attention is coastal infrastructure threatened by sea-level rise. "More than half of the world’s population lives within 50ish miles of the coast line, and regardless of one’s political view on why sea level is happening, it is a real thing," Knowles said, adding that the Ames research team had just spent an entire day with U.S. Navy Chief Engineer and Rear Admiral Lorin Selby looking at the impact of sea-level rise to military infrastructure.

"Tapping into hyper-accelerated tech advances will be one of the only ways to solve some of the long-term design challenges."

Jonathan Knowles

SETI Institute board of trustees member and adviser to NASA

Often lost in popular discussions of how high sea levels are rising is how far in rising waters will penetrate — sometimes hundreds of feet given a 1-foot increase in height, Knowles noted. While so-called long-term horizon thinking suggests designing infrastructure to coexist with higher sea levels, most current endeavors are focused instead on delaying or mitigating the impact of sea level rise on sea walls and other infrastructure. "That’s the human mindset, and I suspect as a species we’ll spend trillions of dollars to continue to hold it back," Knowles said.

In terms of applied technology for maritime infrastructure, Knowles expects a broad mix of things to come, but he pointed to generative design (based on the composition of organic systems) where AEC software on both land and sea could see exponential advances.

"Outfitting existing infrastructure with sensors, capturing data with scanning and photogrammetry to create computable models — like we’ve done with the Arizona project — and feeding every bit of data from the analog world into AI and machine learning systems can speed the growth of generative design," Knowles said. "Tapping into hyper-accelerated tech advances will be one of the only ways to solve some of the long-term design challenges."

Expanding the scan

The reality capture of USS Arizona is seen as a first step in creating contextualized data frameworks within which AI can generate design output to solve marine construction challenges — from historical preservation to climate resiliency. "The model is already spectacular in its ability to overlay and compare data meshes with a variety of tools and identify changes thematically," Kelsey said.

Not that data collection came easy. In addition to working among thousands of daily memorial visitors and in deference to the solemnity of the USS Arizona itself, the team dealt with silty conditions limiting photogrammetry to detailed close-ups and necessitating the use of powerful Class 4 lasers to combat LiDAR refraction. Kelsey credits success of the project to what he calls "typical field innovation R&D, including everything from celebrations to bad language."

Laser scanning was headed up by Denver, CO-based 3D at Depth and included a great-depth-rated, 250-pound, sub-sea LiDAR unit. Austin, TX-based R2 Sonic provided deep water and shallow water sonar scanning using remotely operated underwater vehicle (ROV) units, and San Rafael, CA-based eTrac initiated a comprehensive hydrographic survey while Kelsey and other divers performed the photogrammetry using underwater cameras.

The completed data model is geotagged and capable of aligning its mesh geometry to future surveys for detecting minute environmental and structural changes to both USS Arizona and the memorial building, an incredible advancement over the hand-drawn surveys completed during the post-attack salvage of the ship and updated only once in 1983.

"Everything we did for reality capture is relevant to piers, ports, oil and gas and anyone who designs, builds, operates or maintains maritime infrastructure."

Pete Kelsey

Strategic projects executive at Autodesk

Autodesk even used the data model to 3-D print a 3-foot-long color copy of the ship, which currently resides in the lobby at the company’s San Francisco headquarters, perhaps as a harbinger of new tech advances coming to marine construction.

"This project has opened the maritime infrastructure space for us," Kelsey said. "Everything we did for reality capture is relevant to piers, ports, oil and gas and anyone who designs, builds, operates or maintains maritime infrastructure. We’ve received interest in the technology from the Army Corps of Engineers to private land holders interested in climate change and sea level rise."

That’s if the Navy and National Park Service don’t keep the scanning team busy for the foreseeable future. Based on the successful capture of the USS Arizona, a request has already been made to expand the project to include the entirety of Pearl Harbor, a task infinitely larger than the one Kelsey considered to be once-in-a-career, and one sure to bring its own fair share of tech discoveries, challenges and celebrations.