Most construction workers and site managers are very familiar with the personal protective equipment (PPE) that helps prevent workplace injuries to the head, eyes, respiratory system and other vulnerable areas of the body.

OSHA, the U.S. agency that mandates the use of PPE on construction projects and in other work environments across a multitude of industries, also requires employers to train workers on how to use the equipment appropriately. The agency can dish out major fines if employers don't take this important step,

So, those in the construction industry are used to seeing packaging with instructions about how to use respirators and other face coverings, even as this type of PPE has come into play in the general population as people try or protect themselves from the novel coronavirus.

The instructions available for 3M's N95 respirator, for example, offer a brief, step-by-step tutorial, complete with photos, on how to don the equipment and make sure it's sealed against the wearer's skin. The material also comes with information about which OSHA standard the respirator meets and against which contaminants it protects. The packaging itself also comes with instructions.

Not so for other types of fabric face coverings that contractors have been buying and wearing as protection against the coronavirus. Generally, it's been a free-for-all as far as the types of masks available, whether professionally manufactured or homemade. The accompanying advice on how to wear them and how well they protect the wearer varies as well.

But that could be about to change.

The PPE industry, led by safety standard organization ASTM International, is working on a standard that would specify design and performance criteria for reusable masks. The group, established in July, aims to set requirements for:

- The general construction of masks.

- How the mask is secured to and stays affixed to the user's head.

- How well masks filter out bacterial and solid particulates.

- Inhalation and exhalation breathing resistances.

- Size and fit testing.

- Affixing and removing masks, sizing, cleaning and recommended period of use.

The group is also working to establish how much of this information would be displayed on mask packaging. The standard would not supplant current mask requirements for healthcare workers nor OSHA industry standards.

There have been previous studies about how well widely available masks protect wearers from the novel coronavirus. The general findings have been that thick fabric and a tight fit make for a more effective mask regardless of whether it is handmade or store-bought.

And the ASTM's goal is in alignment with the Centers for Disease Control and Prevention's (CDC) previous statements that masks for the general public primarily should reduce the number of particles emanating from the user but also should provide the wearer with some protection against inhalation of these particles.

Beyond just general recommendations, the ASTM working group said that a national standard that specifies mask design and performance characteristics could help provide a "level playing field" for consumers as they try to find a suitable face covering. There is no official timeline for the development of the standard.

Making sure mask manufacturers abide by some future standard and accurately identify how well their masks protect against the novel coronavirus, however, is another matter.

The ASTM does not enforce its standards. For mask producers to be held legally responsible for meeting the standard, the appropriate governmental agencies must give them weight by including them in applicable codes, laws or regulations. Then, just as with OSHA standards and consumer protection laws, mask producers could be forced to accurately report how well their products protect the public.

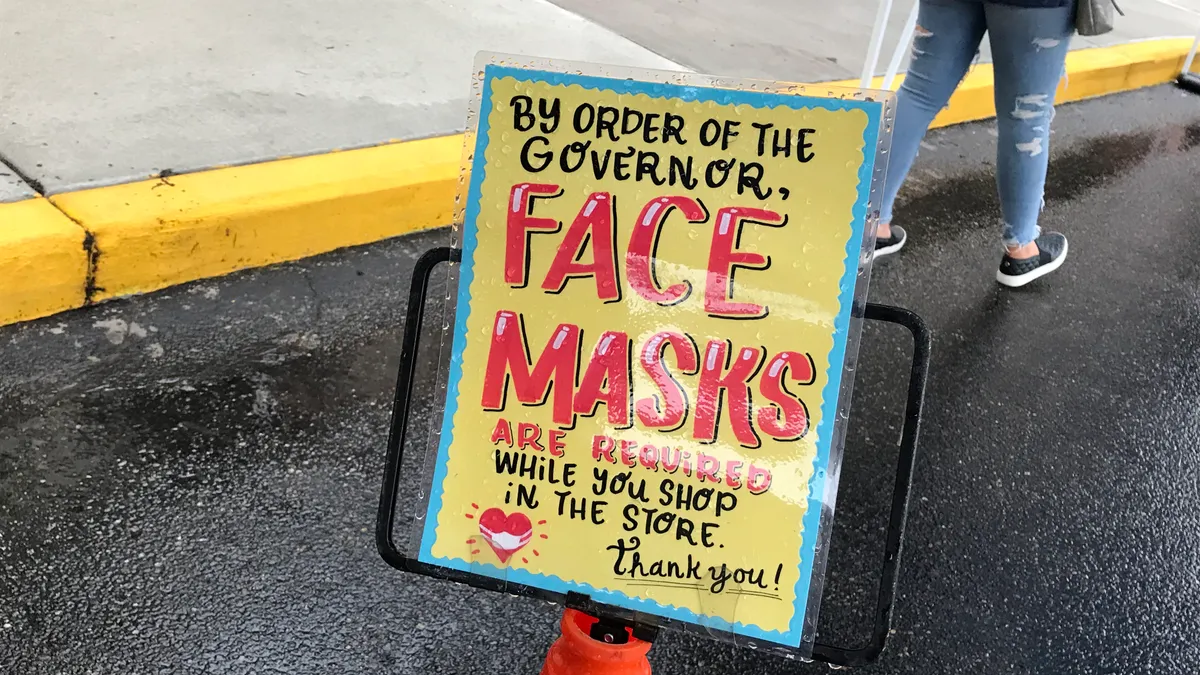

In the construction industry, face coverings to prevent the spread of COVID-19 are recommended and even required on most jobsites and 67% of respondents to a recent Construction Dive survey said that they are an important means of protection.