Dive Brief:

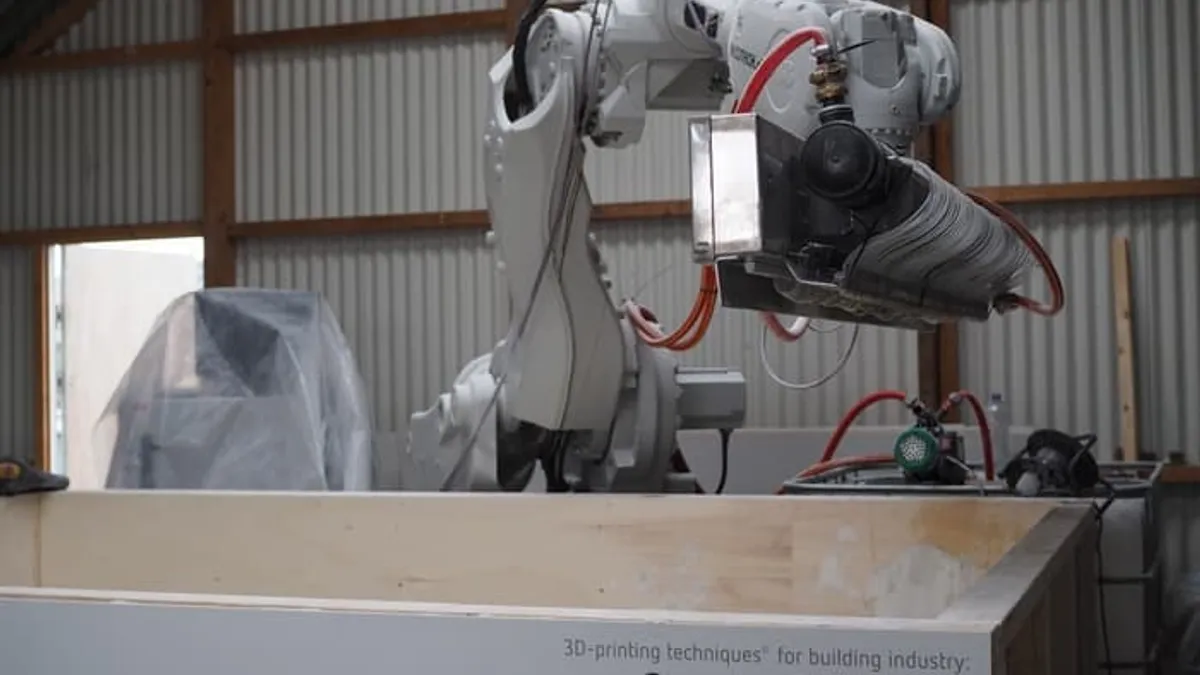

- International contracting giant Royal BAM Group has developed a freeform 3-D robotic printer that can both navigate a construction site and print on its own, according to Global Construction Review.

- The "3D Builder" — which can utilize caterpillar tracks for autonomous movement — uses an interchangeable print head assembly to print with materials such as concrete and stone, and it can recycle its own building waste products.

- Researchers are using 3D Builder to construct the quarter-scale "Landscape House," or "endless house," designed by Dutch design firm Universe Architecture, at the sustainable FabCity experimental campus in Amsterdam as the printer's first project.

Dive Insight:

BAM said the printer uses the D-shape method of 3-D printing developed in Italy by Enrico Dini of Monolite UK and will be able to print with materials like steel and insulation in the future.

A Tennessee company, Branch Technology, has also developed a freeform 3-D printing technology, called cellular fabrication, or "C-Fab." The Branch method, like 3D Builder, also makes use of robotics. The company has used it in the past to construct walls by covering scaffolding forms with spray foam, concrete and stucco but most recently conducted a design challenge for a whole-house project. The Branch team selected a "futuristic" single-family home design from WATG Chicago and should begin construction in 2017.

The BAM robot isn't the only 3-D printed product being created for the job site. The world's first 3-D-printed excavator is set to make an appearance next year at the CONEXPO-CON/AGG and IFPE 2017 event in Las Vegas. The hydraulic-powered excavator is the first large-scale example of the 3-D-printed-steel process.

Also finding real-world applications for 3-D printing technology is Dubai, which announced it will 3-D print 25% of all its buildings by 2030 as part of the Dubai Future Agenda. Last month, Dubai officials revealed the first such building, the world's only fully functional 3-D-printed office building. Builders used reinforced concrete, glass-fiber-reinforced gypsum and fiber-reinforced plastic to build the office in only 17 days.