Average temperature: 11 degrees below zero. Typical wind speed: 140 kilometers per hour. No roads in or out. Active permafrost that’s either frozen solid or defrosted into mud 3-feet-deep, and polar bears — the earth’s largest land predator — roaming the tundra. It’s Iqaluit, Nunavut on Baffin Island, Canada, and for Edmonton-based Stantec, it’s just another place to build a state-of-the-art international airport.

The History Channel was recently on site shooting for a show about "impossible engineering projects," according to Stantec lead architect Noel Best. "There are only three sealift ocean transports that bring material in when the bay is free of ice between August and September, and you can’t build directly on the permafrost or your project will sink during the brief summer thaw," he said.

To complete the impossible build at Iqaluit, Stantec employed a combination of old and new technologies to model building performance, mitigate exposure to extreme climate and optimize the foundation and building envelope that came directly in contact with an unforgiving natural environment.

Stantec isn't alone in the construction industry effort to create more resilient buildings and complete large and complex projects in extreme weather conditions. As international delegates gathered at the COP22 climate summit in Morocco this week to further solutions to climate change, AEC firms are on the front lines of climate resiliency and are leveraging construction technologies to reduce the impact of increasingly frequent extreme weather events.

Water world

Mark Hoekzema, chief meteorologist and director of meteorological operations at Germantown, MD-based Earth Networks — which provides global weather forecasting services to corporate clients for operational strategy and business continuity — said the last 30 years have seen a rise in significant weather events. "For instance, in the Northeast and Mid-Atlantic there has been a 74% increase in rainfall for events categorized as very heavy, and elsewhere the numbers and statistics likewise show that there is something dramatic going on related to climate," he said.

While Hoekzema acknowledged the worth of COP22 and other conversations focused on climate change mitigation, he stressed the critical role of the construction and engineering sector to safeguard people and property from extreme weather events. "It’s unknown how much humans can do to slow climate change, and we need to prepare for things like sea level rise as much as we are trying to figure out how to stop them," he said.

Los Gatos, CA-based Arx Pax co-founder and CEO Greg Henderson is focused on that task, funneling monetization from the company’s hover-board engine technology into building system technology for developing floodplain real estate by floating super structures on a network of post-tensioned concrete pontoons.

In fact, the Arx Pax SAFE Building System doesn’t merely anticipate flood conditions, it aims to introduce them preemptively via canals, boxed culverts or containment foundations to maximize base isolation and create projects resistant and resilient to both extreme flood and seismic events.

Precast pontoons the size of shipping containers provide a broad, stable base for construction, Henderson said, offering developers a foundation that can handle massive loads while allowing for significant horizontal displacement. When it comes to construction limitations, Henderson pointed to the MS Allure of the Seas cruise ship as an analogy, a 236-foot-tall, 16-story, mixed-use, high-density real estate development that weighs 100,000 tons and sits on a 4-and-half acre site floating in water just 30 feet deep.

By comparison, the SAFE foundation system is designed to float residential, institutional and commercial projects in 3 feet of water, drawing notice from AEC players including Doug Robertson, president of structural engineering firm Daedalus, who said designers and builders in seismically active, flood-prone and coastal areas need to take notice of the technology as a "foundation alternative to ensure long-term sustainability."

Pushing the building envelope

Foundational and building envelope technologies and systems figure significantly into projects confronted with extreme construction environments or designed for extreme climate event resiliency. At the Iqaluit airport build out, Stantec was charged with using windows for over 20% of the building façade to maximize the meager natural light in the Arctic Circle.

"Getting the daylight deep into the building was one of the critical design drivers," Best said. "We did a lot of computer modeling on daylight data to achieve the amount of windows mandated by the client."

Despite the preponderance of glass, thermal issues faced by Stantec on the project involved dissipating building heat rather than retaining it. With the 32,808-square-foot building sitting directly on grade, thermal siphons were required to keep the building heat from melting the permafrost and sinking the entire project into the ground. Below a layer of insulation, 5 miles of piping filled with CO2 capture heat and transfer it to above-ground, 6-foot-high vertical radiators where it condenses back into liquid.

Construction projects even in normal environments may have to eventually retrofit to account for the effects of extreme climate on the building envelope. "We’re already seeing a ton of cladding retrofit and anticipate using more systems like THERM as well as aerial drone imaging for envelope thermal modeling," said Matthew Smith, head of the resilience group at Toronto, Canada-based structural engineering firm Entuitive. "Given higher temperatures, more frequent rain and snow, how all of these glass curtain walls will perform is suspect, and being able to model that performance will be huge."

Wind tunnel and water tank modeling

Based in Gelph, Ontario, engineering and scientific consulting firm RDWI has learning labs in the U.S., Canada, Europe and Asia where firms like Entutive and Stantec are utilizing water tank and wind tunnel test beds to model extreme wind conditions for optimizing lateral building loads or — in the case of the Iqaluit airport project — minimizing snow accumulation that can drift on and adjacent to the roof.

By immersing a scale model of the airport into a water tank and introducing sand and current, the Stantec team was able to determine the need to add snow scoops on the roof to force wind eddies that push snow drifting several meters away from — instead of flush against — the airport’s leeward façade. "It’s very simple technology technology, but very graphic and visual," Best said.

Smith said contemporary design aesthetics, particularly for urban residential high-rises, are forcing engineering teams to take a closer look at lateral loads in anticipation of both seismic activity and higher winds associated with extreme weather. Wind tunnel testing on scale models has enabled the team in many cases to move from prescriptive to performance-based design models by inputting test data into ETABS and Perform 3D modeling software.

"A lot of the high-rise engineering in Toronto, New York and London is being driven by wind performance for super tall, super slender towers with small bases," Smith said. "So we really have to model performance under movement."

The need for business continuity

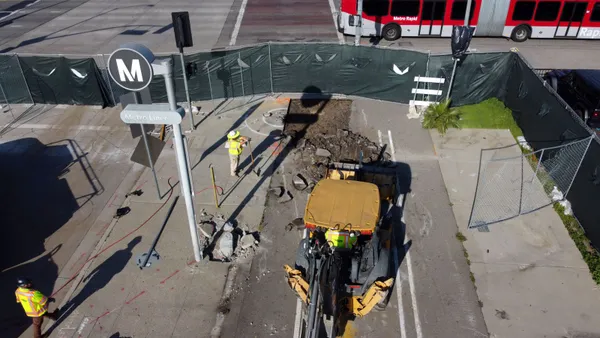

While much of the technology being applied to extreme climate construction is intended to optimize building performance, contractors and engineers are also relying on systems and equipment simply to keep projects moving in adverse environments in places as germane as Rochelle, IL, where Miami, FL-based Dominion Builders was forced to excavate through 4 feet of snow and frozen ground to keep construction of a 177,000-square-foot hydroponic green house on schedule.

"The build started in October, but by the time design was complete, we were in January with temperatures hitting minus 30 degrees," said Dominion Director of Operations Marc Finch. "We used a network of glycol heaters covered with blankets to thaw 45,000 square feet of ground at a time, and then excavated with a back hoe."

Stantec relied extensively on Autodesk BIM 360 to optimize project team logistics at the Iqaluit airport and keep a consistent and reliable flow of materials that Best described as critical given the geographic isolation of the project. "If you are missing a section of pipe, you can’t go down to the local hardware store," he said. "The planning and coordination of electrical and mechanical through BIM allowed us close coordination in advance so the contactor could do detailed take-offs and avoid cost overruns from having to fly materials to the job site."

Continuity has also become a primary driver of sustainable and resilient design and construction overall, particularly after the devastation of Super Storm Sandy put major corporations on the East Coast either out of business or out of operation for long periods of time. The 2012 storm caused $71.4 billion in U.S. damages, according to the National Oceanic and Atmospheric Administration.

"One of the things that came out of Sandy wreaking havoc on the Northeast was an increased attention on businesses to add extreme weather forecasting and consideration into business continuity plans," said Hoekzema, who added that construction teams are also increasingly looking into "now-casting" for real-time weather information, particularly as it relates to lighting probability at high-rise job sites.

According to Smith, the resiliency conversation in building design has shifted from determining whether or not a property can sustain an event like Sandy to how quickly the building — particularly hospitals and essential service buildings, but also office and commercial properties — can be back up and running. "So it is designing with that in mind, to help asset owners reduce the risk of their tenants going out of business," Smith said.