Sue Klawans remembers hand-sketching construction project updates on the backs of blueprints, and even attaching sketches to blueprints via stapler. Now a senior vice president and director of operational excellence and planning at Gilbane Building Company, Klawans has a one-word descriptor for how today’s BIM-empowered AEC sector would interpret what barely a decade ago was bleeding-edge project documentation technology.

“They’d say it’s barbaric,” said Klawans, who this week is gathering with more than 125,000 of her fellow construction professionals in Las Vegas at the conjoined annual meeting of the Associated General Contractors of America and ConExpo, the latter of which is the construction industry’s trade show and technology clearing house that’s so big, it's only held every three years.

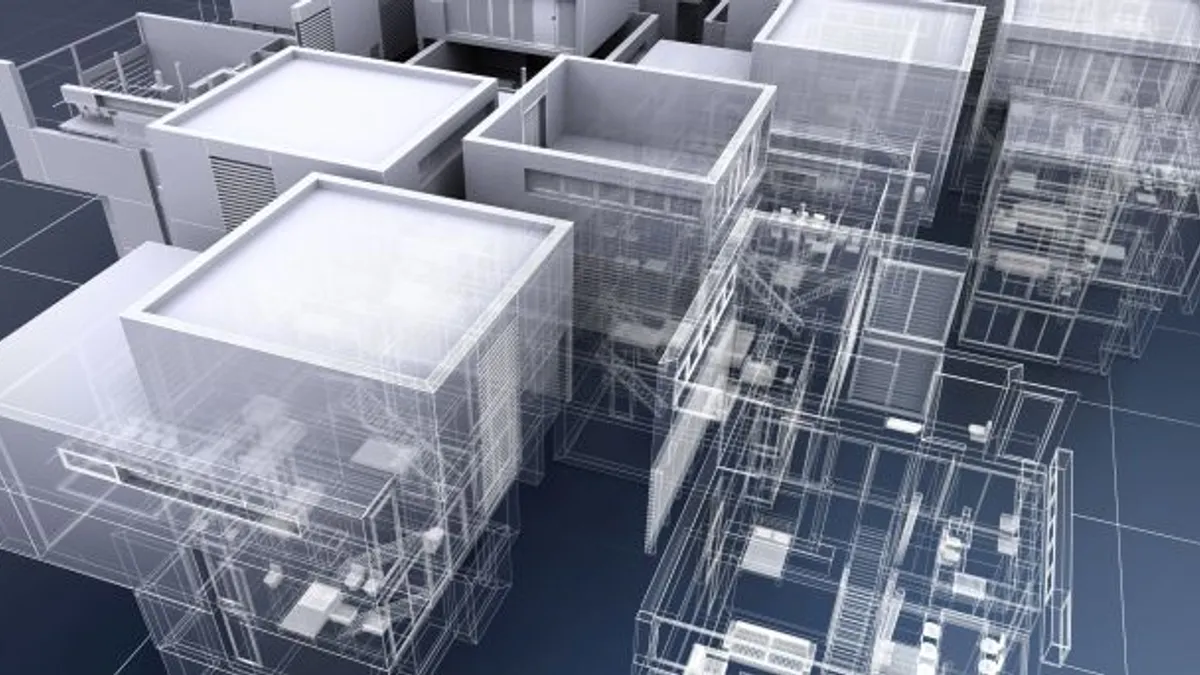

Indeed, when it comes to advances in job site collaboration, Klawans said, “lean” operations and processes dominated AGC leadership discussions in the early going at the Vegas event. One had to look no further than building information modeling (BIM) for the rubric that has significantly advanced construction collaboration by providing a single repository and knowledge resource for project data — from designs to schedules to material lists and more.

“BIM is fundamentally a technology that is making possible the greater process improvements and advancements that we all envisioned,” Klawans said. “Yes, it's a tool, but it's a tool that has removed the notion of hand-offs and wait times in construction management. It's a tool causing us to have one coordinated conversation because we are all looking at the same thing at the same time. The key issue now is how to use that tool to get everyone to new levels of knowledge faster.”

Resistance is futile

Approaching near-universal adoption, BIM has enabled the construction management transformation to a paperless job site and is a foundational system for developing reality technologies including total station and laser-scanning capture, as well as virtual, augmented and mixed reality visualization of construction projects. While pockets of blueprint-dependent individuals and companies remain, software makers and major general contractors agree that the manual creation, collection and communication of project designs and data via paper sets has reached its twilight in favor of BIM as a primary collaboration tool.

“It’s true that from the office to the field, there are still a lot of paper-based workflows,” said Sarah Hodges, director of construction business at San Rafael, CA–based Autodesk, which makes the BIM 360 platform. “Thousands of dollars are still spent littering trailers with paper, and many contractors don’t believe they are even doing BIM — even when the 2-D or paper plans were created using data extracted from a BIM model.”

That insight, Hodges said, will be critical to the widespread acceptance of BIM, particularly when combined with the opportunity to access the same information using a mobile device to save the time and money over printed project documentation, not to mention being able to see changes in real time.

“Thousands of dollars are still spent littering trailers with paper, and many contractors don’t believe they are even doing BIM — even when the 2-D or paper plans were created using data extracted from a BIM model."

Sarah Hodges

Director of construction business, Autodesk

For New York City–based STV, the migration to a virtual design construction shop powered by BIM was promoted by a requirement from Delta Airlines that the company use the tool on the modernization of its terminal at the John F. Kennedy International Airport, in Queens, NY. The result has been improved project speed, certainty of execution and increased business, said Dareen Salama, an associate project controls manager with the company.

“Within two years of standardizing BIM for all jobs, we started winning projects based on the approach, and that is a huge driver for companies like us to adopt BIM,” Salama said. “In this market, you need to be competitive to survive, and technology is a great edge in that regard.”

At Gilbane, an analysis of more than 300 projects completed in 2015 revealed that BIM or a related 3-D hardware or software tool was likewise used on every job.

“BIM is being used on both the biggest and the littlest projects,” Klawans said. “There really isn’t that much resistance anymore. The issue of those not far enough along on the adoption curve is simply one of education, and that’s been matched across the industry with a lot of empowerment to find value.”

Gilbane attributes the use of BIM and other technologies to significant cost savings over the past five years. After decades of static productivity, the labor–hour average across the company's projects has decreased 35%, an efficiency metric Klawans attributes directly to BIM and related construction management tools.

Platform as a portal

As much as BIM has provided paperless innovation to construction management processes, its proponents say even greater advancements — particularly in how BIM accesses, integrates and allows the visualization and analytics of data from other software systems — is yet to come. “The idea of BIM is to put all of the data in one place, and that has not become a fully integrated process yet by any means,” Salama said. “The building is all data and the data can conceivably be connected, so I can click on an object, see all of the info related to it, and then utilize it for whatever I need.”

At Autodesk, BIM 360 is built on the Forge development platform, allowing developers to access code in a viewer where they can retrieve and embed design-file metadata in more than 50 formats. “BIM 360 is a foundational level that supports collaboration and the 'anytime, anywhere' access that enables continuity of data as it is created, augmented and shared at any phase of the project,” Hodges said. “Connected BIM can happen in any number of systems, and third parties can build upon it using Forge as a developer tool."

“Within two years of standardizing BIM for all jobs, we started winning projects based on the approach, and that is a huge driver for companies like us to adopt BIM."

Dareen Salama

Associate project controls manager, STV

Klawans, for one, thinks the evolution of construction technology is following a path of systems consolidation, although not necessarily toward a future where all data-driven functions are controlled by a single technology.

“If we think of these things as a network of databases, then finding an effective way to call and respond to them provides incredible opportunities for advancement,” Klawans said. “Where there are solutions to pair BIM with another software, it provides a leap forward in how you not just effect a better schedule but create a safer and more profitable work environment.”

Not to mention a paperless one. With BIM’s emergence occurring in tandem with broader adoption of mobile devices on the job site, its ability not only to access but also to visualize cloud-stored data makes print sets all but obsolete.

“In just the past couple of years, we have seen a change based on the availability of devices that has hastened adoption,” Hodges said. “Before that, nine out of 10 times the supervisor exploring BIM was back to paper as soon as they wanted to communicate something on the job site. Mobility has opened people’s minds and eyes to using the BIM model — a model that now has value and is accessible outside the office — for connected collaboration across the full project life cycle."