Crews have started the complicated work of cleaning up the site of the Francis Scott Key Bridge’s deadly collapse into the Patapsco River. Central to that effort are barge-mounted cranes, which are being used to pull steel and concrete up from the depths.

Last week the U.S. Navy released underwater images of the collapsed span, which show the magnitude of the job salvage workers face. First, there will be an overall assessment of the wreckage, then the bridge will be cut apart and lifted section by section onto barges and transported away.

This type of operation entails complicated physics and coordination, according to Jeff Ellis, director of field operations for Crane Tech, a Brandon, Florida-based crane services and training provider.

“This is one of those cases where we have to take time to do it right the first time,” said Ellis, who is not involved in the Key Bridge effort, but has experience in water salvage operations. “It’s just so much easier, so much less costly, so much safer to do it correctly.”

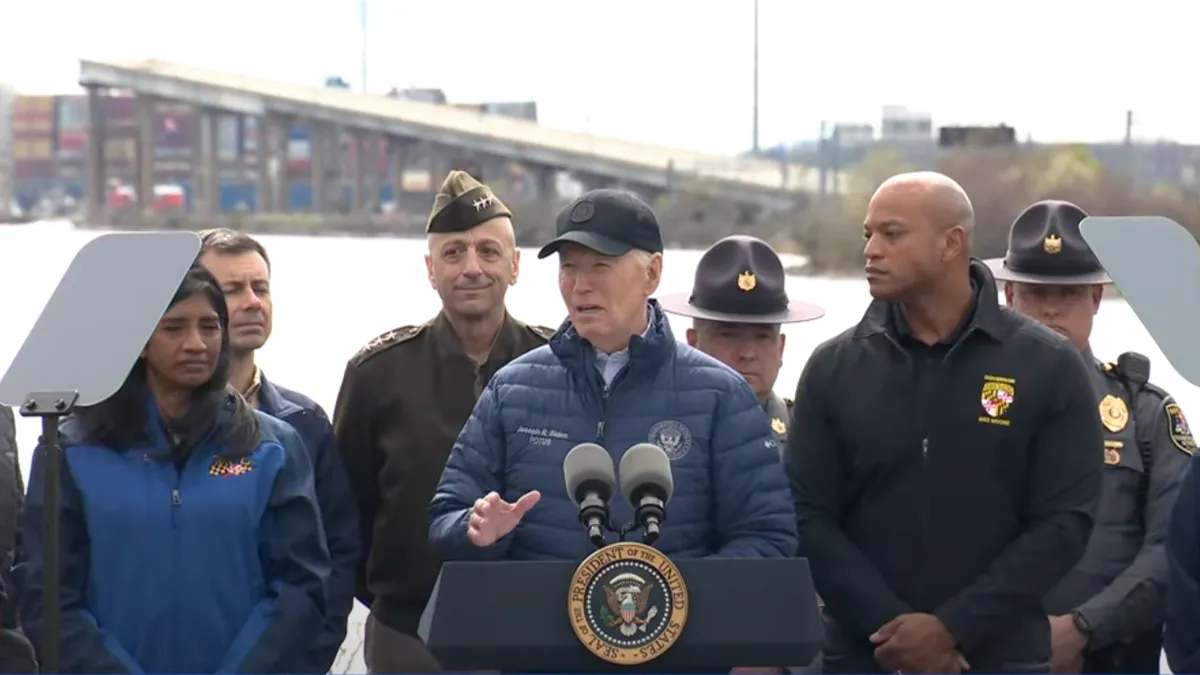

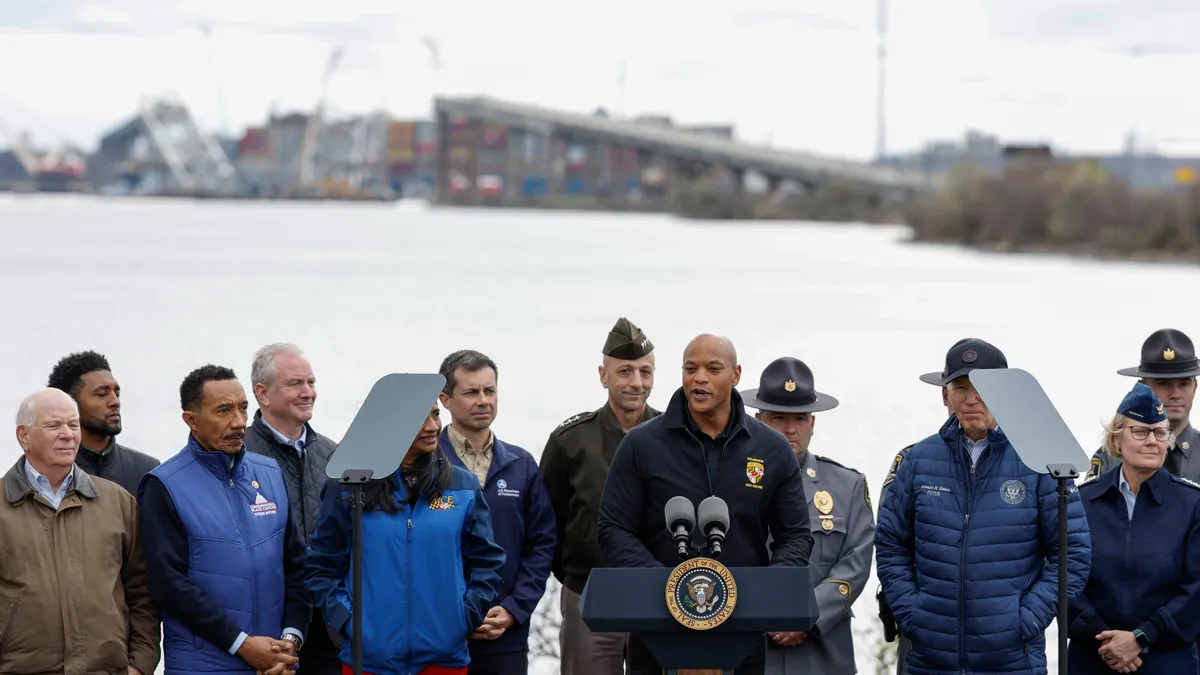

The U.S. Army Corps of Engineers released an updated timeline Thursday to clear a 280-foot wide, 35-foot deep channel by the end of April, and to reopen the permanent, 700-foot wide, 50-foot deep channel by the end of May. However, poor visibility in the murky water has hampered the diving efforts around the bridge structure, according to Maryland Gov. Wes Moore.

Helping with cleanup is The Chesapeake or “Chessy,” a 1,000-ton lift capacity derrick barge and the largest crane on the East Coast that was once used by the CIA.

Also supporting the operation are the Ferrell, a 200-ton lift capacity revolving crane barge; the Oyster Bay, a 150-ton lift capacity crane barge; and another 400-ton lift capacity barge, per a Navy news release, along with an additional 12 crane and support vessels including tugs, survey, dive and crew boats.

Here, Ellis speaks with Construction Dive as he breaks down the process and challenges of retrieving the wreckage of the Key Bridge.

Editor’s note: This interview has been edited for clarity and brevity.

CONSTRUCTION DIVE: Can you tell us what the recovery process will likely entail?

JEFF ELLIS: When they start doing a salvage on the bridge, they need to get the parts and pieces that have collapsed into the water out, without causing any further damage. If part of the cantilever section is laying across the ship, where they pick it up or where they cut it might have an adverse effect and cause another part to go deeper into the water.

Somebody's gotta be the adult supervision and say, “We need to take this piece out first, it's going to weigh about this much,” and plan for that pick and then go to pick number two. It's going to be a thought-out process.

And while getting these pieces up out of the water and clearing the waterway, they are trying to minimize damage to the ship, which has already been damaged quite a bit.

What are some of the challenges in pulling pieces of the bridge out of the water?

The weight of something in the water is going to change dramatically with the current pulling on top and sideways, possibly the wind, and the buoyancy. You could also have the suction of mud in there.

So they need to know what it weighs, because they're not going to be able to measure that as they’re bringing it up. They're going to have to be pretty exact and put in whatever the margin of error they believe it's going to be, probably about 10%.

They're going to ensure that the part they're trying to pick up is well within the capacity of the crane when it leaves the water, not to get it up out of the water and then no longer be able to handle it, which has happened in the past. It's really an engineering nightmare.

How is using barge-mounted cranes different from ones on land?

Whenever you take a barge and add a crane to it, a marine engineer will ensure that the center of gravity is going to be well below the center of buoyancy, so as you pick up a load it's not going to capsize the entire unit. The capacity of it is going to vary with the angle, what they call the list and trim on a barge.

It will lean with the weight added to it, because your boom on that crane is actually like a Johnson bar lever as it deflects in the water. And the more it's out of level, the less you're going to be able to pick, the less capacity you're going to have.

There'll be a list and trim indicator telling them what the moment of physics is, then you're going to have a chart corresponding to that moment of physics showing what the reduced capacity of the crane is.

Also, once it clears the water and you lose that buoyancy, then its actual weight is going to be taking effect on the crane. The last thing you want to do is compound your problem by having an accident on top of this accident.

What are the safety concerns for this type of operation? How has crane safety changed over the years you have been a trainer?

When you have people underwater around this stuff, there's a lot more safety concerns. With divers in the water, we're not just talking about taking somebody from a parking lot to an ambulance, now we're talking about how we are going to get them out of the river, to a boat, over to some kind of triage where they can start getting help.

The whole idea behind a lift planning is to make sure that we're aware of all the hazards, and then we're going to do something about each and every hazard to either abate it, mitigate it, make it go away or deal with it, whatever the case may be. Then they're going to have to make sure it's executed the way that it's planned out.

There was a time when the person that got the most done with the least amount was a hero, until there was an accident.

There was a time that it was acceptable to overextend people and overextend equipment in the name of getting it done. That's no longer acceptable, because we know that it's not cost effective.

Being able to change a culture by education is a wonderful thing. We're all smarter today than we were yesterday, at least I hope so.