After about three years of testing, Autodesk earlier this year released a preview version of BIM 360 Construction IQ, a machine learning tool that analyzes large swaths of project data to rate safety and quality issues by risk level.

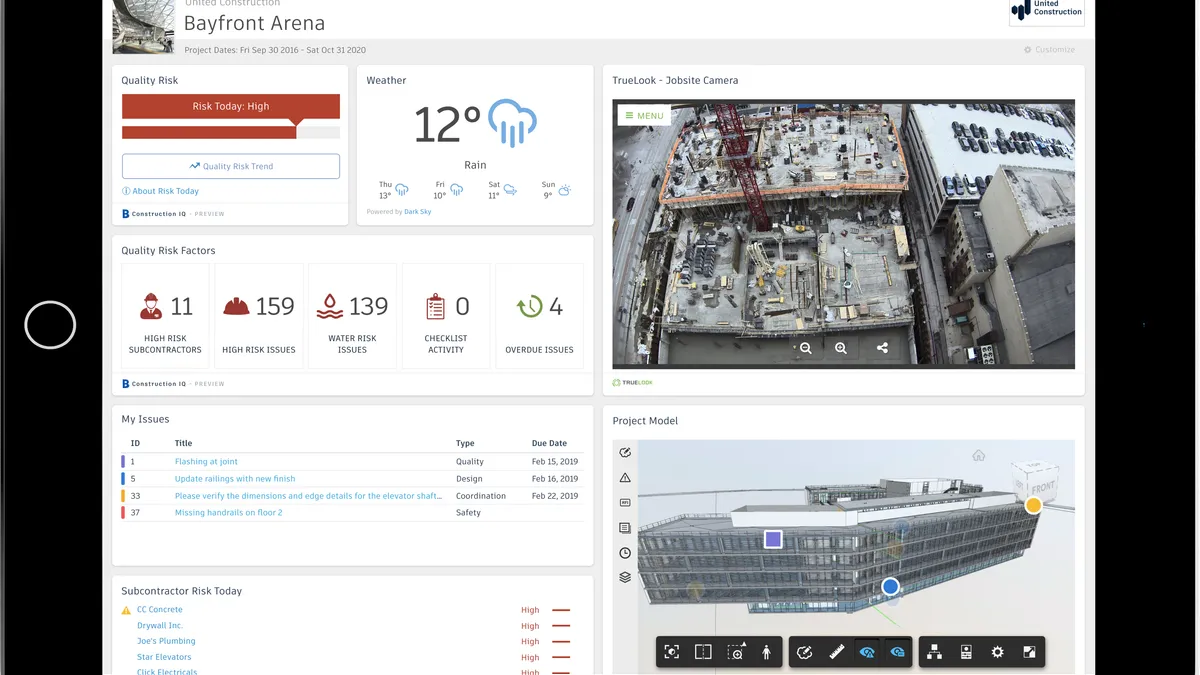

The algorithms can sort through hundreds or thousands of issues from projects using BIM 360 to compile a daily risk assessment dashboard, according to the company, and issues that rise to the top typically involve the risk of a fall, water hazards, a pending safety inspection or overdue action item.

The tool includes two dashboards that tailor data insights to the role of the user. The Project Lead format allows a superintendent or project manager to view the risk level associated with subcontractors and issues on their particular project, while the Executive format provides a VP of operations or director of quality to compare risk across all projects in their account, Autodesk says.

In a beta testing period, contractor BAM Ireland reduced its quality and safety issues on site by 20%, according to Autodesk, “as a result of better decision making” supported by the product. In addition, the pilot found that project staff were able to spend 25% more time addressing high-risk issues, helped by the visibility into trends that the dashboards can provide.

Paric Construction’s VP of technology and innovation, Andy Leek, told Construction Dive that company workflows have changed since implementing the tool during pre-release and now across all projects. “It moves us away from reporting,” he said, where someone has to run a report on a regular basis, disseminate the information and sometimes run further reports based on a leader’s request for more information.

The company now has a project manager, superintendent or project engineer complete a checklist each day with about 50 items and report any issue that they observe on the spot. “Instead of a report having to be generated, the checklist collects all these issues that are automatically feeding into the dashboard,” said Leek.

Users viewing the dashboard can click on any issue to collect further information about it and determine whether the risk assessment is accurate. Autodesk includes the disclaimer that the algorithm’s determination is not always correct, and that some high-risk issues may not be detected as such.

The visibility the dashboards provide also helped steer Paric toward better closeout rates, Leek said. The executive team, in particular, called for an improvement on the 60% to 70% rate that was shown on the dashboard at the beginning of the rollout. “When that became front of mind for our [project executives], operations management and VP of ops, all of a sudden we started to see an acceleration in how quickly these issues are being closed out and understanding why they were being created in the first place,” he said, noting that the firm now closes out 90% to 95% of issues.

In developing the tool, Autodesk wanted to shed light on how the algorithm arrives at its conclusions. “AI in prediction is a black box to people. It’s kind of scary and they don’t know if they should trust it,” Pat Keaney, director of BIM 360 Enterprise Products, told Construction Dive.

“We developed a [user interface] that in a simple and straightforward way shows … some of the key things that go into identifying a high-risk quality issue,” she said. Users can then drill down and more deeply explore the issues, she explained.

For example, Paric has been able to track its personal protective equipment compliance on a more granular level using the tool, according to Leek, by organizing issues according to the type of equipment involved.