Dive Brief:

- American architect Greg Lynn said that today’s composite materials — carbon fiber, fiberglass, structural plastics — combined with fast-drying adhesives could "revolutionize" construction and help contractors deliver all kinds of buildings, even skyscrapers, without the traditional nuts and bolts, according to Dezeen.

- Lynn said using adhesives with composites is a quicker method of construction and that many composites are "lighter, cheaper and stronger" than many of the building materials used today. He said the material can be formed and glued into many different shapes covering long distances.

- Reducing the weight of a skyscraper by using glued-together composites, Lynn said, could save a project money and also reduce building movement during an earthquake.

Dive Insight:

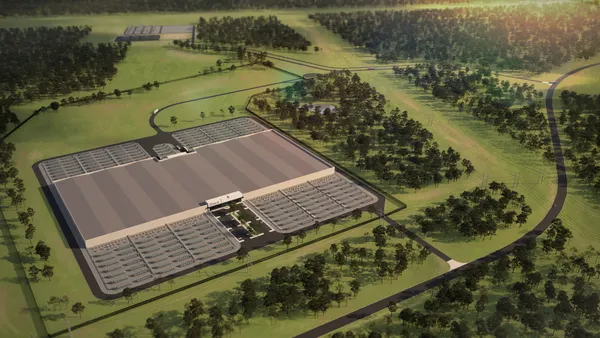

This composite method has already been in use by Apple on its campus "spaceship" in Cupertino, CA. The company used carbon-fiber for the roof on the campus theater, and company officials have said it is the world’s largest such freestanding roof.

Another impressive example of the use of composites, according to Dezeen, is the San Francisco Museum of Modern Art’s modular exterior panels that will comprise the largest composite-based façade in the U.S. In addition, a group from the University of Maine has built 18 "lightweight road bridges" from composite materials as part of its Take the Bridge in a Backpack project. Team members created arches from carbon-fiber tubes, a material they said is light enough to be carried by just a few people.

This is a continuation of a trend toward material innovation in the industry, particularly in the structural arena. In January, material startup BioMason announced millions in investments for its masonry brick alternative, which company officials said gets its strength from the "biological cement" created by injecting microorganisms into sand. The result is a "coral-like" brick that has many residential and commercial structural applications.

Another material that has the potential to be an industry game-changer is the multi-layer engineered wood product cross-laminated timber (CLT). According to the American Wood Council, CLT is highly fire resistant, renewable, sustainable and can significantly reduce a building’s carbon footprint because CLT panels store the carbon absorbed during a tree’s growing cycle. However, overcoming building codes and fire codes, as well as public perception of the safety of working or living in wood high-rises, will be a serious challenge for the plyscraper movement.