Dive Brief:

-

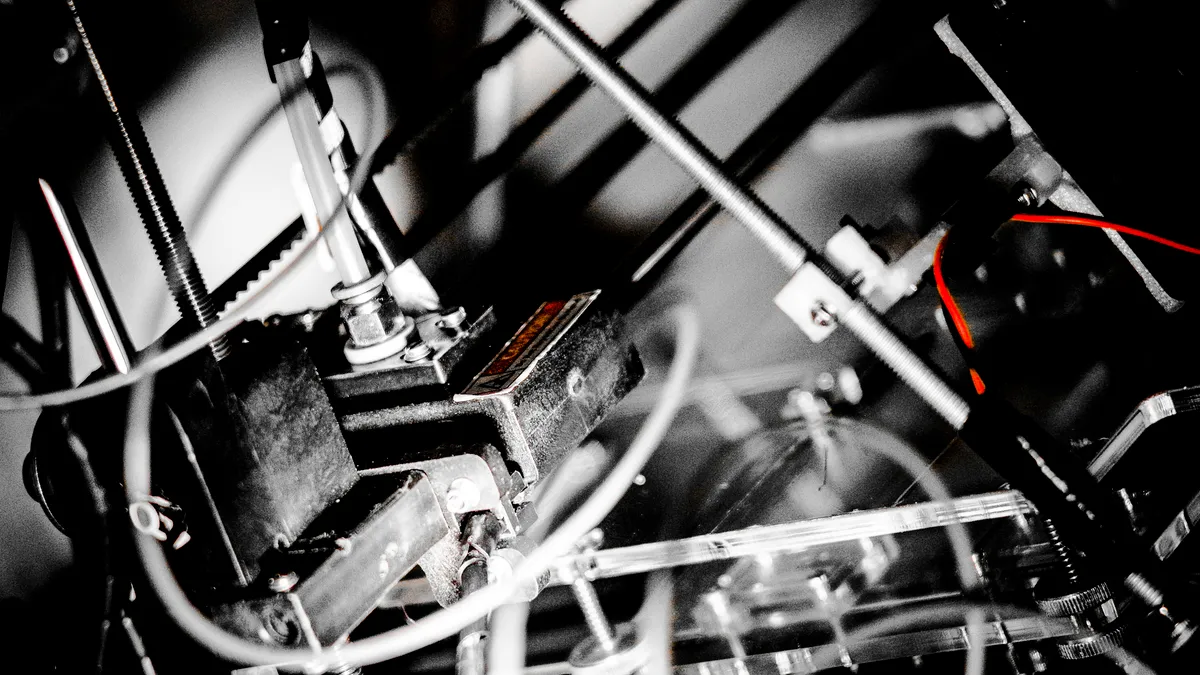

AECOM is delving further into additive manufacturing with the signing earlier this month of a memorandum of understanding with Chinese 3-D printing company WinSun, according to Global Construction Review.

-

Through the agreement, the companies will explore opportunities to work together on projects, particularly in the Middle East, for a three-year period. The MOU could give AECOM an advantage when competing for work in China’s One Belt, One Road initiative, GCR noted.

- The collaboration comes as additive manufacturing broadens from being a way to create components on-demand to a means of quickly constructing entire buildings, evidenced by WinSun’s printing of 10 houses in Shanghai in 2014.

Dive Insight:

3-D printing is growing up — both in the level of detail it can achieve and in the size of its outputs. So far, WinSun has been credited with producing a set of public restrooms complete with drainage and infrastructure, a five-story apartment building and a 12,000-square-foot residence, in addition to the set of houses. More recently, the building materials company with a 3-D printing bent has said it will lease 100 3-D printers to a construction company in Saudi Arabia.

The building method is gaining ground in the Middle East. Last year, Dubai announced that it will use 3-D printing to construct one-quarter of its new city buildings by 2030. A month later, it unveiled a 2,000-square-foot, 3-D printed office building that it says took 17 days to produce. The building, designed by Gensler, Thornton Tomasetti and Syska Hennessy, is the headquarters for the Dubai Future Foundation.

In the U.S., researchers and practitioners are currently looking at 3-D printing primarily for its ability to streamline the construction of components and modules, rather than entire structures.

For example, researchers at the Oak Ridge National Laboratory recently showcased the world’s first 3-D printed excavator, which demonstrates the potential for extruding metal. In September 2015, Oak Ridge, along with SOM, Clayton Homes and others, teamed up to create a 3-D printed shelter and car, the former comprising modules that can be made in the factory and assembled onsite.

With its eye on new fabrication methods worldwide, AECOM is also growing its ranks in the U.S. The company plans to add 3,000 workers in the next six months in a range of roles that will serve the company’s building, defense, energy, environment, transportation and water projects in the country.